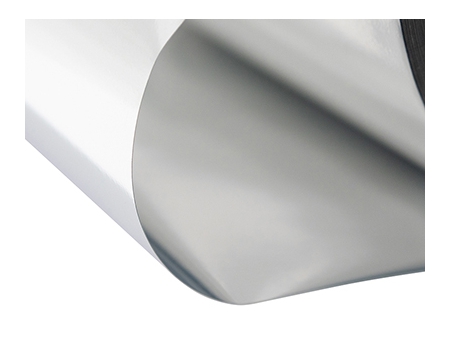

Nano Barrier Film

Designed using modern nanotechnology, nano barrier films are high-performance films. Excellent barrier qualities from its nano-scale porous structure help to stop particles, microbes, chemicals, and toxins. Particularly in settings where conventional films fail, the improved material is meant to provide outstanding protection.

Mostly utilized in vacuum insulating packaging, this nano barrier film provides low heat conductivity, great barrier performance, and long-lasting durability. It improves bending resistance and lessens edge effects by removing the dependence on aluminum foil layers in packaging bags. It is also a dependable alternative for specific uses since it operates really well in high-temperature and high-humidity environments.

What the Features of Nano Barrier Film

- Meets the low thermal conductivity, high barrier, and long life needs of vacuum insulation packaging.

- Eliminates reliance on aluminum foil layers, addressing the high edge effect.

- Improves resistance to high temperature and high humidity conditions.

- Strong inter-layer adhesion and superior bending resistance.

Specifications

| Product type | Test Method | |||||

| Puncture force (N) | 26 | 28 | 31 | 30 | 21 | GB/T21302 |

| Heat seal strength | 63 | 70 | 73 | 60 | 61 | QB/T2358 |

| Water vapor transmission rate (g/m²/day) | 0.05 | 0.03 | 0.05 | 0.05 | 0.0038 | GB1037 |

| Nitrogen transmission rate (g/m²/day) | 4*10⁻⁷ | 2*10⁻⁸ | 3.5*10⁻⁸ | 5*10⁻⁸ | 1.1*10⁻⁷ | Internal testing |

| High temperature aging △kMW/(m·k) 80℃ to 30℃, 65%RH, 28days | ≤1.2 | ≤0.8 | ≤1.2 | ≤1.2 | ≤1 | GB/T39548 |

| High temperature aging △kMW/(m ·k) 70℃, 90%RH, 30days | ≤3 | ≤2 | ≤3 | ≤5 | ≤1.2 | GB/T39548 |

| High temperature aging △K105℃, 48Hours | 3.5 | 2.7 | 5.5 | 3.5 | 3.5 | GB/T39548 |

Need Assistance?

Have questions or want more information? Our team is here and ready to help you.