3J21 Cobalt Based Alloy

Request a Quote

- 5253-2011

3J21 Cobalt Based Alloy

Physical and Mechanical Properties

Density

8.30g/cm³

Melting point

1427°C

Elongation

5-30%

Tensile strength

970Mpa

Yield strength

480MPa

Product Form and Standard Specification

Bar

YB/T 5253-2011

Plate

ASTM F1058 Grade 1

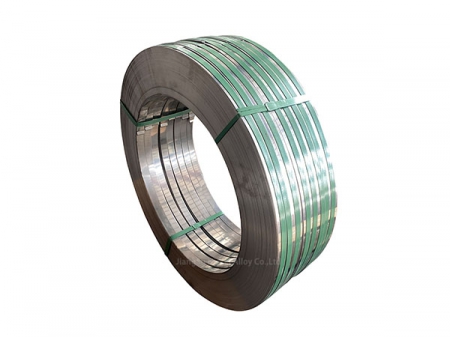

Strip

AMS5833

Wire

AMS5834

Forging

AMS5876

3J21 is a high-performance cobalt-based alloy, distinguishing itself with a unique composition and exceptional performance characteristics, making it essential in aviation, aerospace, precision instrument manufacturing, and other demanding fields. Renowned for its superior elasticity, corrosion resistance, high-temperature stability, and non-magnetic properties, 3J21 is an indispensable material in modern industrial applications.

Features- Non-magnetic performance: Ideal for magnetically sensitive environments, 3J21 alloy is frequently used in magnetic sensors, magnetic shielding, and precision instruments where magnetic interference must be avoided.

- Excellent corrosion resistance: The alloy resists oxidation, vulcanization, and chemical corrosion across a variety of media, making it suitable for chemically aggressive environments.

- High elasticity and fatigue resistance: 3J21 alloy maintains mechanical stability under repeated deformation, making it suitable for elastic elements and high-precision components.

- Precision instruments: Used in components such as tension wires and spiral springs requiring high elasticity, precision, and long-term stability.

- Aerospace and aviation: Applied in engine blades, precision bearings, and elastic structural components with high-temperature and fatigue resistance.

- Magnetic sensors and shielding: The alloy’s non-magnetic nature and material sensitivity make it ideal for sensor components in magnetic detection systems.

- Chemical and petrochemical industries: Suitable for producing corrosion-resistant pipelines and equipment that must operate in harsh chemical or high-temperature environments.

- Medical devices: Used in applications such as artificial joints and implantable medical components, where biocompatibility and corrosion resistance are essential.

Chemical compositions

| Element | Min. % | Max. % |

| C | - | 0.15 |

| Mn | 1.5 | 2.5 |

| Si | - | 1.2 |

| P | - | 0.015 |

| S | - | 0.015 |

| Cr | 19 | 21 |

| Ni | 14 | 16 |

| Co | 39 | 41 |

| Mo | 6 | 8 |

| Be | - | 0.1 |

| Fe | - | Bal |

every aspect of materials testing, so our customers can achieve

consistent and accurate results, every time.

Providing High Nickel Alloys and High Performance Alloys