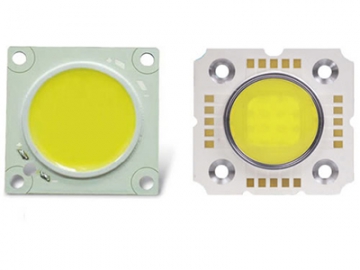

Low Refractive Index Silicone for COB LED Encapsulation

Model:

SR2650-A/B

Product Features

1. The low refractive index silicone comes with high toughness.

2. It provides excellent resistance to heat, cold and UV.

3. The organic silicone comes with superior adhesion to metal, PPA, ceramic and other substrates.

Main Applications

The low refractive index silicone is mainly used for encapsulation of COB LEDs.

Packaging

1kg/bottle

| Before curing | Physical properties | SR2530A | SR2530B |

| Appearance | Colorless and transparent | Colorless and transparent | |

| Refractive index(25°C) | 1.41 | 1.41 | |

| Density (g/ cm) | 1.03 | 1.03 | |

| Viscosity(25°C ) mPa·s | 4500 | 3000 | |

| Mixing ratio | 100 | 100 | |

| Viscosity after mixing(25°C ) mPa·s | 4000 | ||

| Operable time(25°C) | 8h | ||

| After curing | SHORE hardness | 45 | |

| Refractive index(25°C) | 1.41 | ||

| Tensile strength ( Mpa ) | 6 | ||

| Elongation (%) | 150% | ||

| Light transmittance (450 nm, 1 mm) | 94% | ||

Notes:

1) Curing condition: first cure 100℃ x1 hours post cure 150℃ x3hours

2) The low refractive index silicone should be stored at room temperature in an indoor dry and ventilated place without direct sunlight. Shelf life is 12 month.

3) Viscosity of this LED encapsulation material is measured by NDJ-79 rotary viscosimeter.

4) Above table is only for reference use. Contact us detailed molding process.