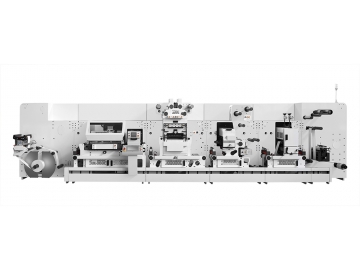

Electronics Screen Printing Machine

Process requirements

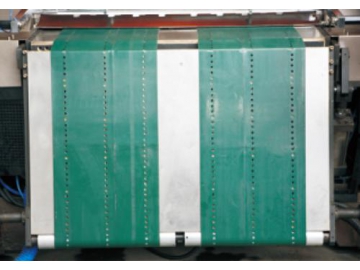

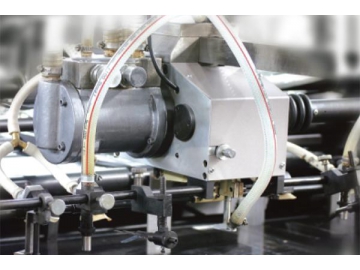

For the printing of panels of household appliance and electronic products, it delivers on the requirements for sheet thickness and precision. Thus, the printing equipment must guarantee uniform pressure and clear printing lines. During the drying process, higher drying temperature is also required.

All fully automatic stop cylinder screen printing machines can be used on 0.05~0.08mm thick PET film or PVC film, while ensuring color register precision.

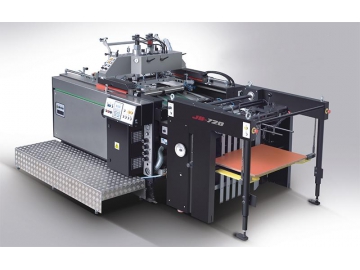

In the comprehensive view of cost and efficiency, JB-720AQ or JS-720 can meet your requests. This two models have a maximum printable size of 720mm×520mm, and a highest printing speed of 2800 sheets/hour.

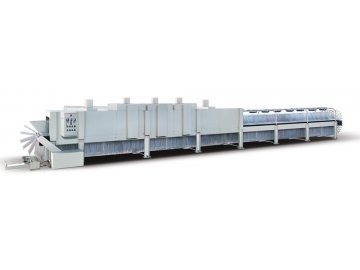

Matching with the 720AQ, JS-720 fully automatic screen printing equipment, we recommend that you choose JB-800P infrared and ultraviolet dryer with an effective curing width of 800mm that can directly penetrate the ink to realize drying form inside to outside.

Matching the printing machine and drying equipment, you can choose the JB-800S fully automatic paper stacker to complete the follow-up automatic collection efficiently, which can achieve a maximum printing size of 800mm×600mm.