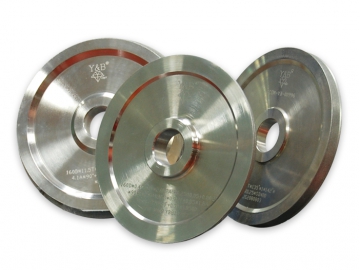

Electroplated Diamond/CBN Grinding Wheel

Request a Quote

At Yubao, we design and manufacture precision electroplated diamond and CBN wheels to meet or exceed your grinding applications.

Followings are our standard type of electroplated diamond & CBN grinding wheels.

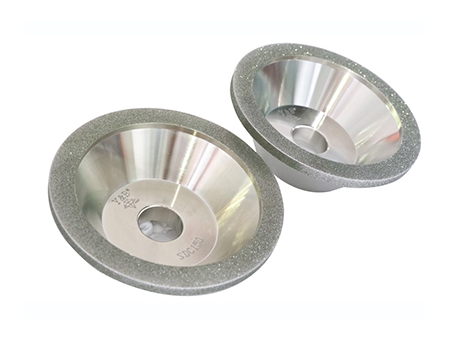

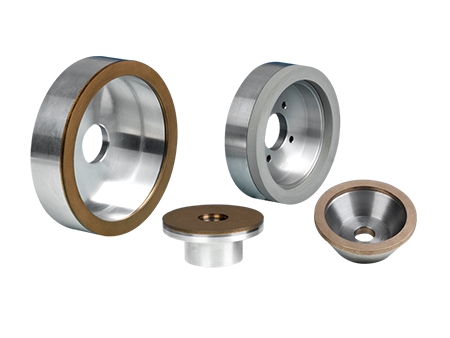

Ideal for grinding internal carbide thread milling cutter.

| Outer diameter (D) (mm) | Overall thickness (T) (mm) | Arbor hole diameter (H) (mm) | Fillet radius (R) (mm) | Abrasive thickness (U) (mm) | |

| 100/125/150 | 6/8/10 | 25.4/31.75/32 | Customized | 1-10 |

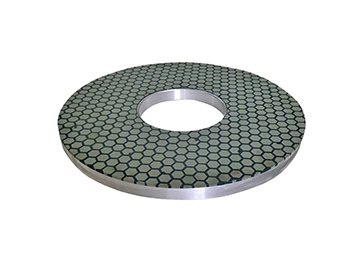

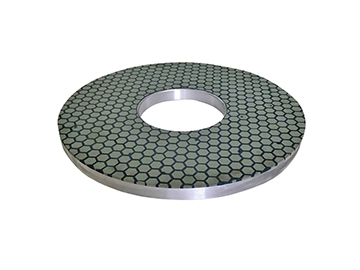

Ideal for rough grinding, fine grinding and chamfering processes on materials such as glass and sapphire.

| Outer diameter (D) (mm) | Overall thickness (T) (mm) | Arbor hole diameter (H) (mm) | Fillet radius (R) (mm) | Abrasive thickness (U) (mm) |

| 100/125/150 | 6/8/10 | 25.4/31.75/32 | Customized | 1-10 |

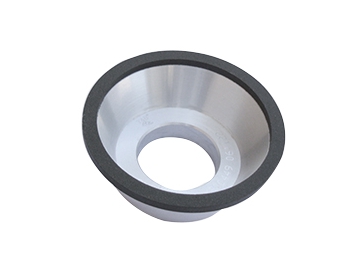

Ideal for grooving process of hard alloy cutters like drill bits, spade bits, and thread taps.

| Outer diameter (mm) | Overall thickness (mm) | Arbor hole diameter (mm) | Fillet radius (mm) | Abrasive thickness (mm) | |

| 80/100/125/ 150/200 | 6-10 | 12.7/25.4/ 31.75/32/127 | 3-5 | 2-10 | |

| 80/100/125/ 150/200 | 6-25 | 12.7/25.4/ 31.75/32/127 | 0.5-5 | 2-10 |

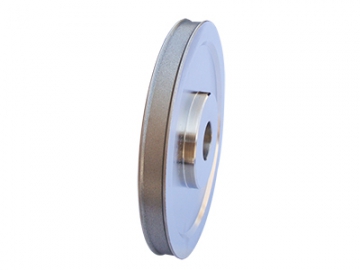

Ideal for profile grinding of blade tools.

| Outer diameter (mm) | Overall thickness (mm) | Arbor hole diameter (mm) | Profile wheel height (mm) | Abrasive width (X) (mm) |

| 80/100/125/150/ 180/200/250/300 | 8-20 | 25.4/31.75/32/127 | Customized | 1-10 |

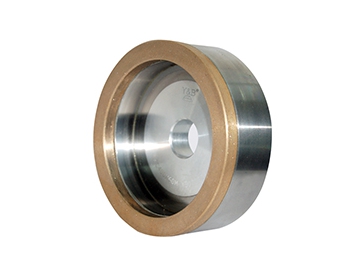

Ideal for the precision grinding of piston rings.

| Outer diameter (mm) | Overall thickness (mm) | Arbor hole diameter (mm) | Abrasive thickness (mm) | Fillet radius (mm) | Abrasive width (X) (mm) | |

| 80/100/125/ 150/180/200 | 6-25 | 12.7/25.4/ 31.75/32/127 | 1-10 | 0.5-5 | 2-10 |

Ideal for grinding of alloy cutting tools, including milling cutters, drill bits, spade bits, step reamers, gravers, etc, also ideal for form grinding in the processes of gemstones, corals, rubber, shells, marbles, fine ceramics, carbon fibers, etc.

| Outer diameter | Overall thickness | Arbor hole diameter | Abrasive width | |

| 12 | 8-12 | 6 | 2/3 | |

| 14/15 | 8-14 | 6 | 2/3 | |

| 8-14 | 6 | 2/3 | ||

| 16/18/20 | 8-16 | 10 | 2/3 | |

| 8-16 | 10 | 2/3 | ||

| 8-16 | 10 | 2/3 | ||

| 23 | 12-20 | 10 | 2/3 | |

| 25/30/35 | 2-20 | 5/6/8/10/12 | 2/2.5/3/4 | |

| 2-20 | 5/6/8/10/12/13 | 2/2.5/3/4 | ||

| 2-20 | 10/12/12.7/16 | 2/2.5/3/4/5 | ||

| 40/45/50 | 0.2-20 | 8/10/12/12.7/16 | 2/2.5/3/4/5 | |

| 0.2-20 | 8/10/12/12.7/16 | 2/2.5/3/4/5 | ||

| 0.2-20 | 8/10/12/12.7/16 | 2/2.5/3/4/5 | ||

| 60 | 0.2-20 | 8/10/12/12.7/16/ 19.05/20/22.23 | 2/2.5/3/4/5 | |

| 75/80 | 0.4-30 | 10/16/19.05/ 20/22.23/25.4 | 3/4/5 | |

| 100 | 0.4-35 | 20/22.23/25.4/31.75/32 | 3-6 | |

| 115 | 2-20 | 20/22.23/25.4/31.75/32 | 3-6 | |

| 125 | 0.8-35 | 20/22.23/25.4/31.75/32 | 4/5/6/8/10 | |

| 150 | 1-35 | 25.4/31.75/32/40 | 4/5/6/8/10 | |

| 175 | 3-35 | 31.75/32/40 | 5/6/8/10/16 | |

| 180 | 10-40 | 31.75/32/40/50.8/75/76.2 | 5/6/8/10/16 | |

| 200 | 1-40 | 31.75/32/40/50.8/75/76.2 | 5/6/8/10/16/20 | |

| 250 | 10-60 | 50.8/75/76.2/101.6/127 | 5/6/8/10/16/20 | |

| 300 | 3-60 | 75/76.2/101.6/127/203 | 5/6/8/10/16/20/25 | |

| 350 | 12-50 | 127/203 | 5/6/8/10/16/20/25 | |

| 400 | 3.5-50 | 127/203 | 5/6/8/10/16/20/25 |

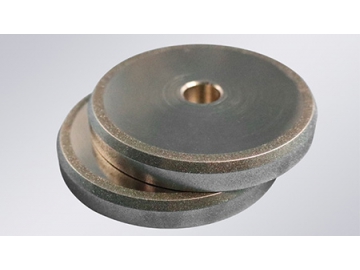

Ideal for grinding alloy cutting tools, including milling cutters, drill bits, spade bits, step reamers, gravers, etc.

| Outer diameter (mm) | Overall thickness (mm) | Arbor hole diameter (mm) | Arbor hole width (mm) | Abrasive width (mm) | Abrasive thickness (mm) | |

| 75 | 25 | 19.05/20 | 10 | 3/5/6/8/10 | 2-6 | |

| 100 | 25-40 | 19.05/20 /31.75/32 | 10 | 6/8/10/12 | 2-6 | |

| 125/150 | 25-40 | 19.05/20 /31.75/32 | 10 | 8/10/12/15 | 3/4/5/6/8 | |

| 200 | 30-50 | 31.75/32/40 | 12/15 | 8/10/12/15/20/25 | 3/4/5/6/8 |

Related Product

Related products

Send Message

Other Products

Most Recent

More

Other Products

Videos