Ink-jet, pigment and dye Grinding Application

High-quality printing ink manufacturing solutions

Ink is printing material composed of uniformly dispersed pigment, dyes, resins, solvents, lubricants, surfactants, fluorescents, and other materials. It is extensively used for printing books, cloths, packaging materials, electronic circuit boards, and more. The ink particle size is crucial to the printing quality. The finer the ink particles, the clearer and smoother the printing effect, with less ink consumption. Because of this, inks should be ground one or more times to reduce the particle size before use.

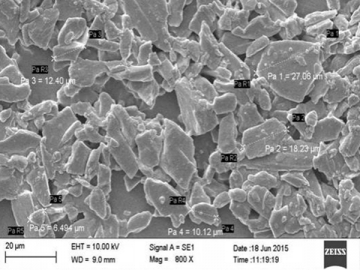

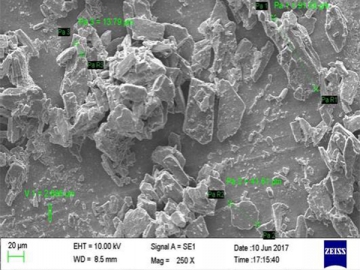

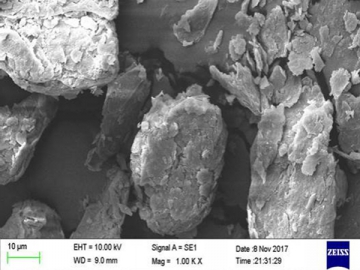

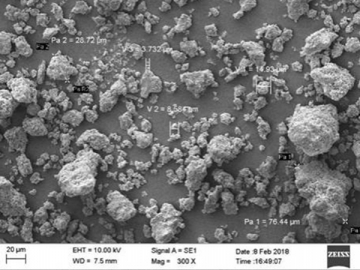

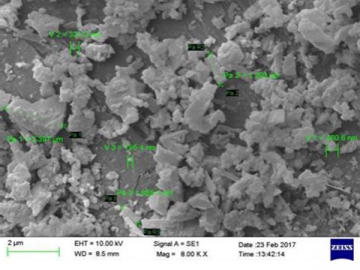

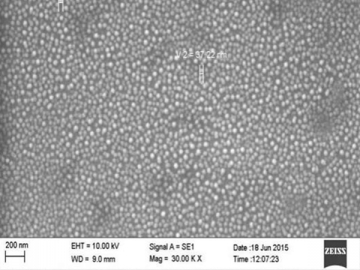

Shown below are the ultrafine grinding results of inkjet ink using our grinding mills. It is clearly displayed the raw material particles are coarse and irregular in shape with a wide particle size distribution. After an ultra-fine grinding process, these particles reach nanometer sizes and feature an excellent sphericity, extremely narrow particle size distribution and outstanding dispersity, thus significantly improving the ink quality. Our grinding mills have been successfully applied to the production lines of numerous international ink companies, giving them a great capacity improvement and considerable economic benefits.

- Before grinding

- After grinding

| Characterized size | Feed | Products |

| D50(μm) | 18.00 | 0.04 |

| D90(μm) | 31.00 | 0.05 |

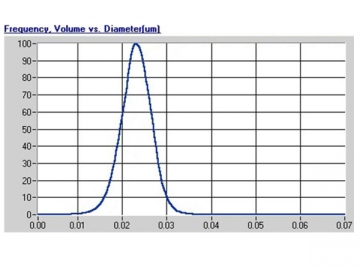

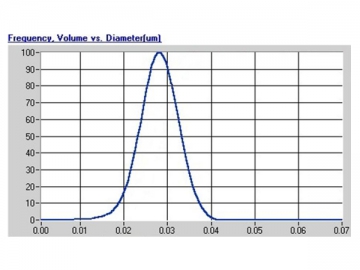

- Particle size distribution of contact lens ink (green)

- Particle size distribution of contact lens ink (blue)

| Sample | D25(μm) | D50(μm) | D75(μm) | D90(μm) |

| Green ink | 0.021 | 0.023 | 0.025 | 0.034 |

| Blue ink | 0.025 | 0.028 | 0.031 | 0.040 |