Investment Casting Steps

- Produce master pattern

Create original pattern with wax, silica sol, clay and others.

- Create casting molds

The master die is made to master pattern.

- Produce wax patterns

Produced in two ways. One is to pour the wax into the mold and shake it until the inner surface is as thick as 3mm (0.12inch). Then repeat the operation until generating the required pattern thickness. Another method is to fill the mold with molten wax and cool it into a solid object.

- Assemble wax pattern

Adopt skilled wax drop technology to process wax mold assemble can produce multiple wax molds and assembled into a large model for casting in one batch pour.

- Produce the shell

Yanshan Precision Machinery co., Ltd has 400 meters of cantilever production line to reach over 100 tons production capacity. We also invested in the construction of a new rapid drying workshop to greatly shorten the product cycle and improve production efficiency with rapid drying technology.

- Dewax

Place ceramic mold in furnace or autoclave for evaporation melting. Increase the heating speed to ensure the shell will not damage in dewax process and the outer wax surface can be quickly melted and expelled. In some cases, the mold can be drilled before heating to reduce stress. The wax that comes out of the mold can also be recycled.

- Burn out preheating

Heat the mold to 870~1095°C to remove the water and residual wax, then sinter to mold.

- Pouring

Put investment mold into sand. Yanshan Precision Machinery co., Ltd is equipped with 150 kg medium frequency induction furnace melting steel for casting metal workpieces.

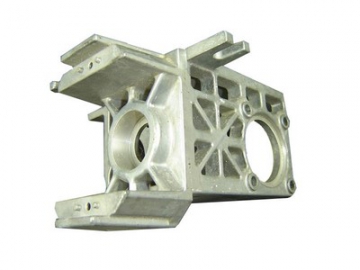

- Release the casting

Casting products can be obtained by cleaning or grinding the finished metal workpieces after casting by external force.

-

Yanshan Precision Machinery co., Ltd also provide machining service for high-precision workpieces according to the requirement of customers.