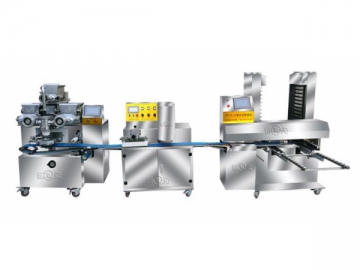

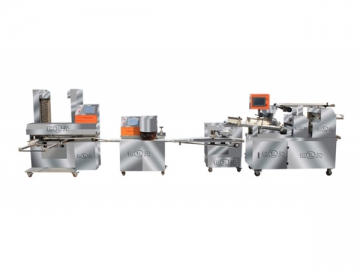

Lap Tape Production Line

Request a Quote

View All: http://coatingslitter.com/lap-tape.html

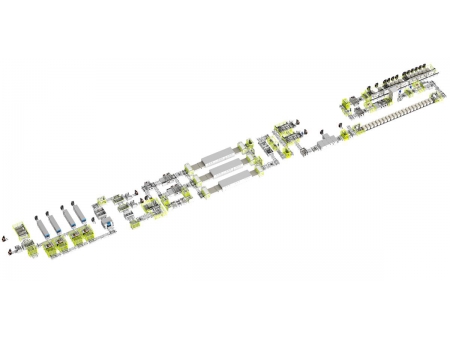

Complete coating line for making self-adhesive waterproof tape

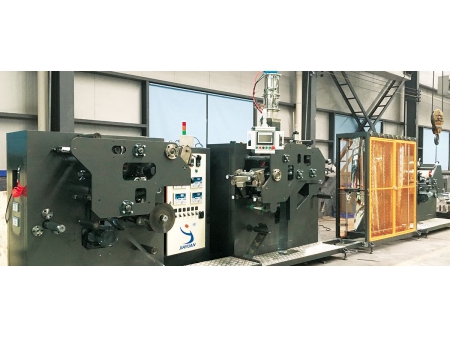

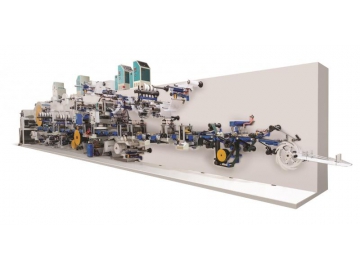

The lap tape production line is designed for waterproof material manufacturers, achieving coating on both sides simultaneously. Ideal for producing polymer self-adhesive sealing strips and special waterproof auxiliary materials for underground pipe galleries, suitable for waterproofing, construction, leak repair, sealing, wind power, battery, etc. industries.

Specifications

| Effective Coating Width | 100-300mm |

| Coating Weight | 80-500g/m² |

| Machine Speed | 1-30m/min |

| Power Supply | 380v±15PHz |

Parameters can be adjusted according to specific customer requirements.

Features

- Coating on both sides can be conducted simultaneously.

- Simplified sand placement system is optional upon request.

Frequently Asked Questions

Web coating technology involves continuously applying one or multiple layers of liquid onto a substrate to create a new structure with specific properties. The liquid can be adhesive, barrier layers, protective coatings, etc.

The roll-to-roll processing is a film processing method where various fluid materials are embedded, coated, printed, or laminated onto a flexible roll-shaped substrate, and the material is continuously transported from one roller to another (unwind to rewind).

Research has shown that thermoplastic coatings are more wear-resistant than epoxy coatings. Due to their flexibility, thermoplastic coatings can better withstand the impact of solid components. Some coatings have better wear resistance because they can be applied in thicker layers.

The food industry particularly employs non-stick coatings. These coatings are resistant to high temperatures and easy to clean. These properties are also beneficial for many other applications.

Related products

Send Message

Other Products

Most Recent

More

Other Products

Videos