Medical Lyophilized Powder Formulation Processing Equipment

The processing of medical lyophilized powder mainly considers the composition of feedstock, the degree of homogeneity and constant volume dilution. Besides, as for design the formulation processing system of medical lyophilized powder in practice, one key is to design the volume of tanks according to the product yield to make sure the equipment in normal operation.

One medical lyophilized powder case NJR did is shown below for your reference.

Project time: 2017

Client address: Jiangsu province

Product: medical lyophilized powder

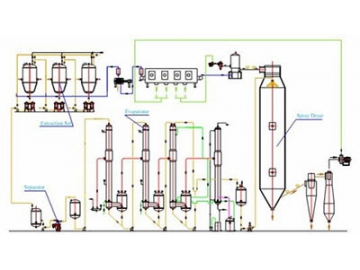

- Graphic design plan

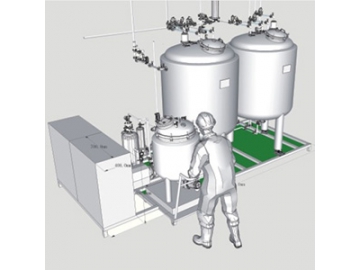

3D design

3D design Working scene

Working scene

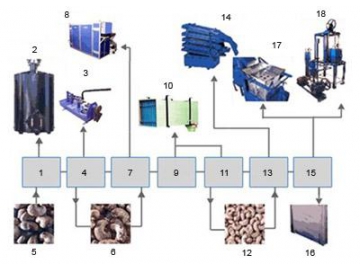

Use the dosing system to formulate two kinds of product. The processing of the first product needs five steps. After the formulation and filling, all the tanks and piping should have in-line sterilization.

Plan in detail

NJR designs three tanks including the concentrate tank, dilution tank and high level tank.

- Equip the feed valve of the concentrate tank with control valve and install weight sensor module on the supporting leg of vessel to achieve precise control on weight of feedstock.

- The dilution tank uses magnetic mixer to control liquid to a constant volume and the degree of homogeneity.

- Carry out the SIP (sanitize in place) for in-line sterilization.