Post-Processing

At RZD, we offer a variety of post-processing services for our plastic products after molding and demolding. These treatments are essential for ensuring that the products are safe and ready for their intended purpose. We stand ready to provide you with these services, so you can be confident that your plastic products are ready for use.

Using air spraying as the current popular method, a layer of paint is applied to plastic parts according to the desired effect. Compressed air is forced through the nozzle of the spray gun, creating a negative pressure that draws paint up the suction tube before spraying it as a mist onto the part. This ensures the paint forms a uniform coating, giving an even and smooth finish.

Silk screening is an efficient method of producing a high-quality product. It involves post-processing the surface of the parts to give it a vibrant and polished finish. The equipment is simple to use, and the setup and design are straightforward and cost-effective. Additionally, silk screening can be applied to a variety of products.

Annealing is a process used to relieve stress in plastic products. The molded plastic product is placed in a hot environment, like hot water, hot air, or liquid paraffin, at a constant temperature for a certain amount of time. After this, the temperature is slowly lowered back to room temperature in order to get rid of the internal pressures within the plastic.

The amount of time a plastic part must be annealed is dependent on the characteristics of the plastic itself, as well as the parameters of the product being molded (thickness, shape, and molding conditions).

Conditioning plastic parts with moisture is a post-process that involves submerging the newly-demolded items in hot water. Its purpose is to separate the air and shield the plastic parts from oxidation, while at the same time accelerating the absorption of moisture. It's mainly used on polyamide and other materials that are hydrophilic and prone to oxidation. This treatment helps to stabilize the size, color, and performance of the plastic product and ensures that moisture absorption is achieved as quickly as possible.

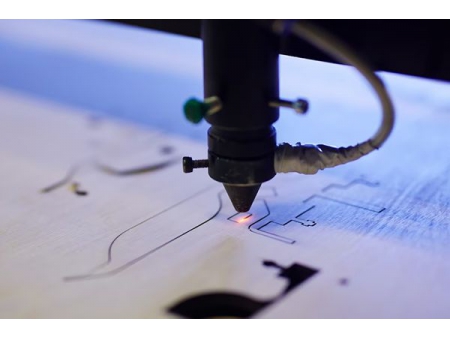

After the plastic product is removed from its mold, there can be extra bits of material such as gates, flashes, etc. These extra materials can be damaging to the part's appearance and functionality. Fortunately, these can easily be removed with simple gate trimming tools.

The plastic and rubber products provided by RZD will be subject to our strict post-processing services to ensure the performance of the products provided.