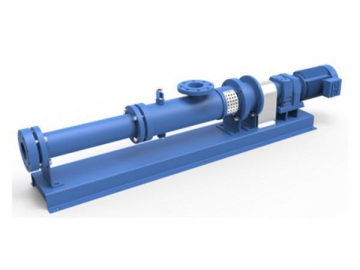

Progressive Cavity Pump Shaft Seal Selection

Subtor pumps can be produced with two different styles of shaft seals that the customer can choose from. One is a packing seal and the other, a mechanical seal.

Application

Packing seals are preferred because of the simplicity of their design. They are typically applied in pumping conditions with lower demands and for conveying media with low temperature and minimal corrosive properties. They are used in pumps designed for transporting mud cake, slurry, solid control plants, oily sewage, and other low demand mixtures.

Advantages

• Wide range of applicable media, safety seal

• Low cost, easy replacement

• Simple operation, simple installation

Disadvantages

• The shaft can slow the transmission power and wear down faster than other types of seal.

• A small amount of leakage is permitted because the packing seal is self-lubricated.

Subtor's solution to packing seal's problem

• Surface hardening on the coupling shaft

After surface hardening, the coupling shaft shows improvement with high wear-resistance and longer service life.

• Media with water flushing

Not only can water flushing cool the shaft, but it can also aid in lubrication and sealing.

Advantages

• Tight seal, no leakage

• Long service life, light vibration sensitivity

• Nearly no friction between seal head and shaft, small loss of mechanical efficiency

• Wide application: Mechanical seals are suitable for outdoor conditions with low temperatures, high temperature, high vacuum, high pressure; it remains tight for substances which are corrosive, abrasive, inflammable, explosive and toxic.

Disadvantages

• Complex structure, high installation requirements

• Hard to exchange--disassemble drive part first and then take off along the shaft

• Long procurement lead time, expensive

Subtor's solution to the mechanical seal's problems

To prolong the service life of mechanical seals and prevent damage and excessive wear over time, Subtor provides several flushing schemes for customers, all of which are in accordance with API1682 standards.

• Thermal dissipation through flushing

• Minimizing flushing fluid temperature

• Change the pressure within the seal chamber

• Clean the processing fluid

• Air side control to improve working condition

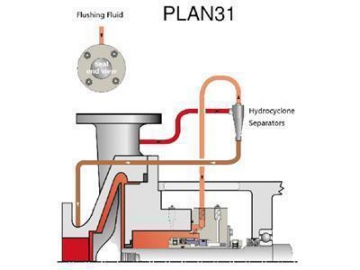

Plan31

Principle: Use the cyclone hydraulic separator to remove impurities in the flushing liquid and seal chamber. This also dissipates heat.

Application: For working conditions when lubrication and dissipation are dependent on the transmitted substance. Sometimes the substances contain solid foreign matter which can cause issues.

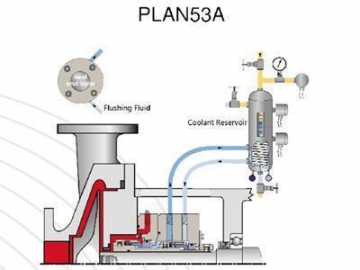

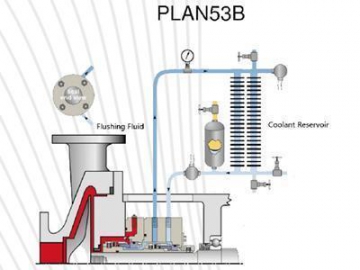

Plan53 (A/B)

Principle: Use the liquid seal tank to pressurize spacer fluid and perform out circulation for the pump. This isolates the substance and dissipates heat.

Application: transmitted substances include liquids with high saturated vapor pressure like light hydrocarbons, toxic liquids, heat transfer liquids, solid liquid mixtures, etc.

Working conditions include mixed pump and vacuum.

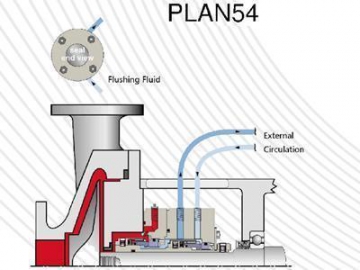

Plan54

Principle: pressed spacer fluid runs in the outer circulation system; transmitted substance needs to be isolated with external tap water.

Application: transmitted substances includes liquids with high saturated vapor pressure, such as light hydrocarbon, toxic liquid and heat transfer liquid, solid liquid mixture and etc.

Working conditions include mixing pumping and vacuum.