Double Shaft Horizontal Mixer

Non gravity mixer for dry bulk materials

The double shaft horizontal mixer ensures thorough and efficient blending of dry bulk materials thanks to its internal non-gravity mixing mechanism, where materials interweave and diffuse effectively in a weightless environment. With a large mixing capacity ranging from 4000L to 8000L and double shafts rotating at 55 rpm, it offers higher throughput compared to single-shaft mixers. It can blend precisely measured materials such as sand, cement, gypsum, fly ash, calcium carbonate, lime powder, and additives uniformly within approximately 180 seconds, resulting in consistent, high-quality finished products. Featuring a unique hydraulic gate structure, discharge is completed within 10 seconds, minimizing residue. Additionally, a material distributor positioned at the outlet directs the final mixture either to packaging lines for bagging or to bulk loading systems via a dry powder screw conveyor, depending on production requirements. This horizontal mixer is widely used for producing various dry mortar products such as anti-crack mortar, thermal insulation mortar, bonding mortar, plaster mortar, floor mortar, and mid-to-high-grade wall putty powder.

| Model | ||||||

| Total volume (L) | 1500 | 2000 | 3000 | 4000 | 6000 | 8000 |

| Volumetric coefficient | 0.4-0.7 | 0.4-0.7 | 0.4-0.7 | 0.4-0.7 | 0.4-0.65 | 0.4-0.65 |

| Mixing power (kW) | 18.5 | 22 | 30 | 45 | 55 | 75 |

| Discharging power (kW) | 3 | 3 | 3 | 3 | 4 | 4 |

| Weight (kg) | 2900 | 3700 | 4800 | 6300 | 7600 | 8900 |

Note: Due to ongoing equipment improvements and performance enhancements, the final specifications may differ slightly from those stated.

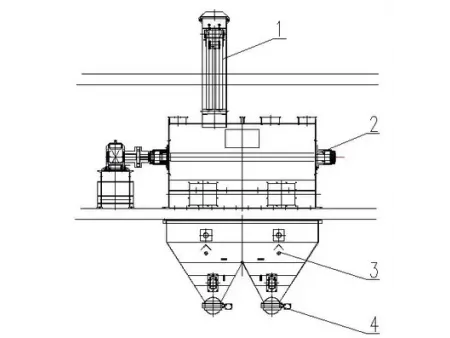

- Dust Collector

- Mixing Chamber

- Mixed Material Storage Tank

- Butterfly Valve Discharge

Ideal for efficiently blending dry construction materials, including specialty mortars, wall putty powder, gypsum plaster, tile adhesives, and self-leveling compounds. This double-shaft mixer uniformly combines materials to meet required strength and consistency standards for high-quality finished products.

- The double shaft drive is equipped with frequency conversion technology, enabling operators to precisely adjust rotational speed according to different material requirements, ensuring optimal mixing results.

- An industrial-grade gearbox replaces traditional chain-driven mechanisms, providing greater durability and significantly reducing maintenance demands.

- A combined mechanical and pneumatic sealing structure prevents any leakage, minimizing material waste and maintaining a cleaner operating environment.

- Replaceable, wear-resistant mixing paddles and liners are capable of handling the production of up to 300,000 tons of mortar without needing replacement, significantly enhancing operational reliability.

- Mixing blades, available in plowshare or paddle configurations, ensure thorough and uniform blending, effectively meeting diverse production needs.

- The large-door hydraulic discharge system provides rapid unloading with minimal residue, substantially reducing downtime and improving overall production efficiency.

- High-speed chopper blades incorporated in the mixing chamber deliver quick shearing and dispersing of materials, achieving shorter mixing cycles and consistently higher mixing accuracy.

-

Shaft End Sealing System

A dual sealing mechanism, combining both mechanical and pneumatic seals, effectively prevents oil leakage at the shaft ends. This ensures the mixing process remains clean and contamination-free, preserving the integrity and quality of the materials.

-

Hydraulic Discharge System

Equipped with a manual door-opening mechanism, the hydraulic discharge system allows manual operation to safely open discharge doors even during power outages, ensuring uninterrupted workflow and ease of maintenance.

-

Auxiliary Arm

The auxiliary arm assists in securely closing the discharge door, providing safer and easier operation.

-

Mixing Device

Two mixing shafts rotate in opposite directions at precisely calculated speeds, creating a zero-gravity environment through centrifugal force. This allows the materials to blend thoroughly and evenly, achieving excellent mixing efficiency.

-

Auxiliary Locking Device

This device ensures the discharge door remains securely locked, effectively preventing any material leakage during operation.

-

Shaft-End Oil Seal

An automatic lubrication system continuously lubricates the main unit, effectively protecting the shaft ends and ensuring smooth, reliable operation.

Shandong Jiangyu New Materials Co., Ltd.

Industry: Development and production of new metal-based functional materials