Rapid Tooling

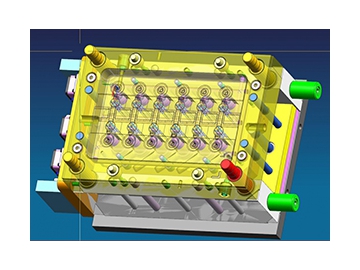

Rapid Tooling is a way to simplify the mould structure for low cost & short lead-time. It describes a process that is the result of combining rapid prototyping techniques with conventional tooling practices to produce a mold quickly from CAD data in low cost and less time relative to traditional machining methods.

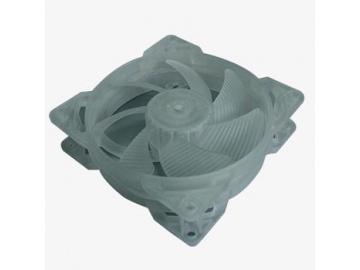

It’s commonly used in the field of rapid injection moulding, based on the low-volume requirement. Nice Rapid manufactures its own tooling and pre-hardened P20 tool steel, to make the cavity, core and ejector plates. They are then fitted into a Master Unit Die with standard tooling components, in order to produce injection moulded parts.

The main advantages of rapid tooling are tooling time is much shorter than for a conventional tool. Time to first articles can be less than one-fifth that of conventional tooling; tooling cost is much less than for a conventional tool. Cost can be below five percent of conventional tooling cost. But the tool life is less than conventional tools.