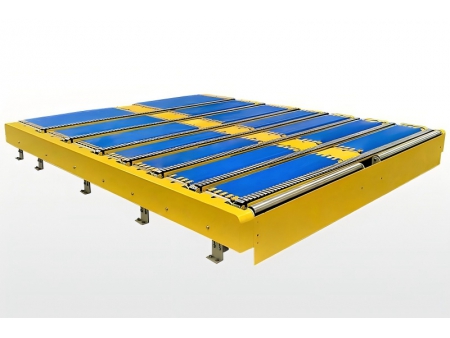

XY Transfer Conveyor

Request a Quote

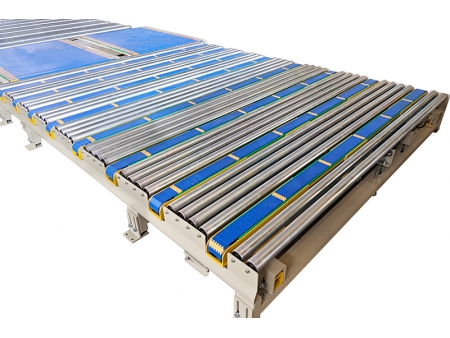

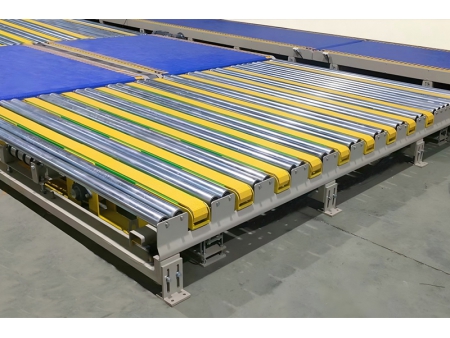

XY transfer conveyor is a multi-directional automated system designed specifically for corrugated board production lines. Through intelligent coordination between an independent X-axis (horizontal) conveying structure and a Y-axis (vertical) conveying structure, it allows for efficient and precise multi-directional material flow in complex production scenarios. Its main functions include horizontal receiving, vertical transport, sorting, and stacking of corrugated boards. This conveying system is suitable for printing, die-cutting, stacking, and other processes, making it especially effective in workshops with limited space and highly variable logistics routes.

- Seamless Multi-Direction Switching: Independent X-axis (horizontal) and Y-axis (vertical) conveying structures combined with a synchronous belt drive system to dynamically adjust conveying paths, supporting straight horizontal movement, vertical transfer, and sorting—reducing downtime and adapting to diversified production layouts.

- Compact And Efficient Design: Interlaced layout of transfer modules and synchronous belts optimizes space utilization. The lifting module adopts German ContiTech airbag lifting technology, ensuring smooth and reliable operation, especially suitable for confined workshop environments.

- Total power: ≥3 kW (customization available)

- Linear conveyor type: Modular belt conveyor/roller conveyor (optional)

- Vertical lifting coveyor: Modular belt conveyor/chain conveyor (optional)

- Lifting system: German ContiTech airbag

- Dimensions: 2500 (L) × 2500 (W) mm / 3600 (L) × 2500 (W) mm (customizable)

- Optional features: Intelligent sensors and PLC control system for automated line integration