Chemical Anchoring Adhesive, MT-500

Structural Adhesives

Injectable adhesives for anchoring rebar and threaded rod in concrete and masonry

Chemical anchoring adhesive is a high-performance two-component adhesive with epoxy and hardener, developed for modern structural reinforcement, retrofitting, and anchoring applications. Packaged in a durable dual-cartridge system and applied through a static mixing nozzle, the adhesive ensures thorough and consistent on-site mixing.

Certifications & Standards

- Complies with GB 50367-2013 (Code for Design of Reinforcement for Concrete Structures)

- Certified under ETA for use in both cracked and non-cracked concrete

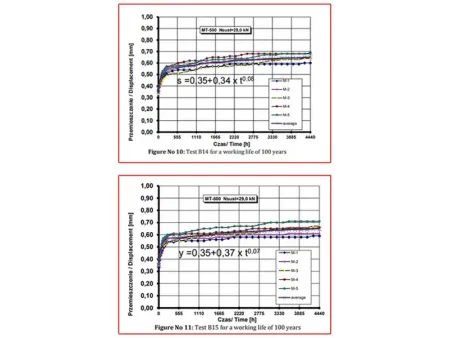

Designed for demanding structural environments, it offers a long working time combined with fast load-bearing performance. It delivers exceptional resistance to seismic loads, impact, and fatigue, tested up to 2 million cycles. The structural anchoring adhesive is engineered to withstand hot and humid aging for over 100 years, maintains strong performance in acidic and alkaline conditions, and exhibits zero creep, non-toxicity, and no odor, making it suitable for both interior and enclosed applications.

The chemical anchoring adhesive is widely used for post-installed rebar, threaded rods, and anchor bolts in buildings, tunnels, bridges, metro systems, and industrial structures where long-term stability and certified reliability are essential.

| Property | Standard Requirement | Test Result | ||||

| Grade A | Grade B | |||||

| Colloidal performance | Splitting tensile strength | ≥8.5MPa | ≥7.0MPa | 19.57MPa | ||

| Bending strength | ≥50MPa | ≥40MPa | 77.5MPa | |||

| Compressive strength | ≥60MPa | 107.6MPa | ||||

| Bonding Capacity | Steel-to-steel tensile shear strength | ≥10MPa | ≥8MPa | 21.3MPa | ||

| Bonding strength of concrete and ribbed steel bars under the constraint drawing condition | C30 | ≥11.0MPa | ≥8.5MPa | 13.8MPa | ||

| C60 | ≥17.0MPa | 14.0MPa | 19.2MPa | |||

| Steel-to-steel T impact peeling length | ≤25mm | ≤40mm | 0mm (no crack) | |||

| Heat distortion temperature | Method B with bending stress of 0.45MPa | ≥65℃ | ≥60℃ | 67.0℃ | ||

| Nonvolatile content | ≥99% | 99.8% | ||||

| Resistance to environmental factors | Resistance to hygrothermal aging | ≤12% | ≤18% | 4.4% reduction | ||

| Resistance to heat aging | ≤5 | No requirements | 2.9% reduction | |||

| Resistance to freeze-thawing | ≤5 | 3.4% reduction | ||||

| Base Material Temperature | Installation Time | Gelling Time | Full Curing Time |

| -5℃~0℃ | 5h | 30h | 96h |

| 0℃~10℃ | 4h | 22h | 72h |

| 10℃~20℃ | 2h | 14h | 48h |

| 20℃~30℃ | 45min | 9h | 24h |

| 30℃~40℃ | 30min | 4h | 12h |

- Delivers excellent pull-out resistance, compressive strength, and load-bearing capacity.

- Suitable for a wide range of hole diameters and embedment depths; oversized holes can even enhance bonding in small-diameter anchors.

- Suitable for use on various base materials, offering strong adhesion to most structural surfaces.

- Maintains shape and performance under sustained load at room temperature for long-term anchoring reliability.

- Resists moisture, chemical exposure, freeze–thaw cycles, and aging, suitable for use in wet, flooded, or low-temperature holes, including water-drilled installations.

- Minimal shrinkage during curing ensures high bonding accuracy and strength retention.

- Long shelf life of 18 months with durable cartridge packaging designed to resist damage during transport and storage.

- Suitable for both structural and non-structural components

- Compatible with cracked and non-cracked concrete in strength classes from C20/25 to C50/60

- Designed to perform under static, dynamic, and fatigue loads

- Applicable in dry and damp concrete conditions

- Works with smooth-walled holes created by water-drilling

- The MT-500/W underwater variant is suitable for fully submerged installations

- Zhuhai Xingye Expressway South Extension Tunnel

- Kunming–Yuxi High-Speed Railway (Kunyu HSR)

- Chengdu Metro Line 7

- European ETA Certification Report

- Batch Quality Inspection Report

- Material Safety Data Sheet

- Moist Heat Aging Resistance Report

- Total Volatile Organic Compounds (TVOC) Report

- Mechanical Performance Test Report

- Ethylenediamine Content Test Report

- Flammability Classification Report

- Electrical Resistance Test Report

- Non-Toxicity Verification Report

- Packaging: 16 cartridges per box, with a net capacity of 500 ml per cartridge

- Gross weight: Approximately 14.9 kg per box

- Carton dimensions: 380 mm × 190 mm × 290 mm (L × W × H)

- Shelf life: 18 months when stored in standard room temperature conditions

- Storage requirements: Keep away from direct sunlight, open flames, and heat sources

Have a question or need a custom quote? Fill out the form and our engineering team will get back to you soon.