Hammer Crusher

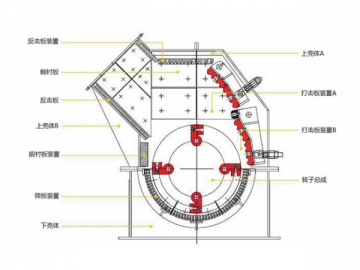

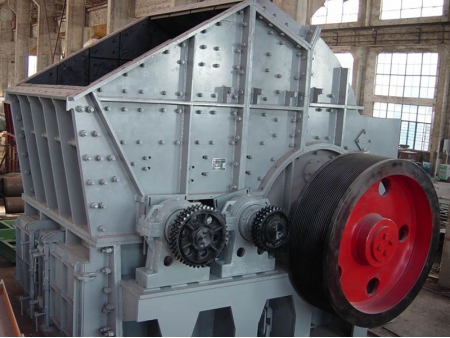

A hammer crusher is an important raw material preparation unit in the autoclaved brick production line. The hammer mill is mainly composed of crusher housing, rotor, main bearing and support, hammer, liner plates and driving system.

Features of the Hammer Crusher

1. Each part of the housing is connected using bolts. Upper cover, lower body and side wall are engineered from carbon steel plates by welding method. There is seal between housing and shaft, preventing dust leakage.

2. The main shaft of the size reduction equipment is fabricated from high quality alloy steel, with ultrasonic flaw detection and quenching and tempering treatment. It is equipped with a flywheel at one end which enables the rotor to store a certain amount of energy in motion to reduce the perk load of motor and alleviate the wear of hammer.

3. Rotor disc and hammer pin hole are made from high manganese steel with carburizing treatment to improve wear resistance, and the hammer is cast in new type high quality chromium manganese steel for longer service life than ordinary hammers.

4. High manganese liner plates and impact plates with quenching treatment come with exceptional resistance to wear and impact.

| Model | Number of hammer ( pcs ) | Feed size ( mm) | Discharge size ( mm ) | Output (t/h) | Weight (t) | Power (kW) |

| | 16 | <100 | <15 | 5-10 | 0.8 | 4P-11 |

| | 20 | <100 | <15 | 8-15 | 1.2 | 4P-18.5 |

| | 20 | <220 | <15 | 10-25 | 1.5 | 4P-22 |

| | 24 | <350 | <15 | 20-50 | 3.8 | 4P-55 |

| | 28 | <400 | <15 | 20-75 | 5.5 | 4P-75 |