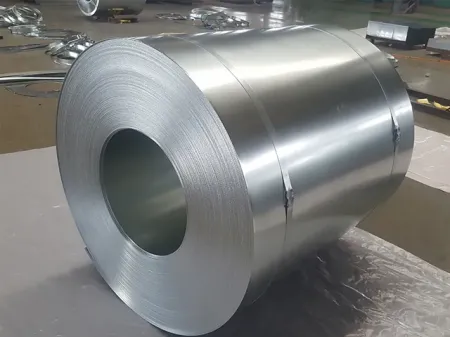

Hot Dipped Galvanized Steel Sheet and Coil

Flat-Rolled Steel

- Thickness 0.18-3.75mm

- Width 800-1500mm

- Coil inner diameter Ø508/Ø610mm

- Coil weight max. 28t

- Standard St01Z, St02Z, SGCC, SGC340, SGH400, DX51D Z, CS

- Zinc coating class range Z20-Z275

- Zinc coating layer thickness max. 275 g/m²

- Surface finish Regular spangle or Zero spangle

- Production capacity 20 production lines, 800,000 tonnes of processed steel per year

- Minimum order quantity 20 tonnes

Worldwide delivery from the Philippines available upon request

| Steel Grade | Thickness (mm) | Width (mm) | Inside Diameter (mm) | Weight (MT) |

| 0.35~2.0 | 1000~1600 | 508 or 610 | <25 |

| Steel Grade | Thickness (mm) | Width (mm) | Inside Diameter (mm) | Weight (MT) |

| 0.23~2.3 | 800~1250 | 508 or610 | <10 | |

| 2.5~3.5 | 800~1250 | 508 or610 | <10 | |

| 0.6~2.0 | 1000~1600 | 508 or610 | <25 |

Hot-dipped galvanized steel coils are widely recognized for their outstanding corrosion resistance and versatility. The production process begins with cold-rolled steel, which undergoes cleaning and annealing in a reducing atmosphere before being immersed in molten zinc under controlled conditions. This results in a uniform, smooth zinc coating that adheres tightly to the steel surface. Even if the coating is scratched or the edges of the steel are exposed, the zinc layer continues to provide effective protection. Its enhanced corrosion resistance makes it a preferred choice for various industries, ensuring long-term durability and reliability.

We offer a range of galvanized options to meet specific customer needs:

- Spangled galvanized steel: Features a distinctive crystallized pattern, often preferred for its classic look.

- Spangle-free galvanized steel: Provides a smooth, uniform finish suitable for applications requiring a sleek surface.

- Zinc-Aluminum Coated Steel: Combines enhanced corrosion protection with a refined appearance.

Our galvanized steel sheets & coils are treated primarily with chrome-based passivation, which is known for its superior corrosion resistance. Additionally, we offer:

- Chrome-free passivation for environmentally sensitive applications.

- Hexavalent chromium-free passivation, aligning with global environmental standards.

- Anti-fingerprint film for enhanced surface protection.

For customers requiring pre-painted steel, we enhance the galvanized substrate with a skin-pass process, improving surface smoothness and ensuring excellent paint adhesion.

| Zinc Coating (Spangle) | Regular spangle (SR) | Key applications include: Construction:Used in residential building projects,roofing,structural components,ceiling panels,balconies,window frames,storage units,garage doors,heating systems,rain gutters,and HVAC ductwork. Furniture Industry:Suitable for wardrobes,desks,bookshelves,cabinets,counters,signage,and decorative lamp covers. Transportation Sector:Ideal for car bodies,trailers,containers,highway guardrails,and ship partitions. Home Appliances:Frequently used in refrigerators,washing machines,air conditioners,microwaves,vending machines,and range hoods. Miscellaneous Uses:Advertising boards,meters,speaker casings,and waste bins. |

| Spangle-free (F) | Ideal for painted surfaces requiring excellent adhesion. | |

| Galfan zinc-aluminum coated (ZA) | Commonly used as a substrate for pre-painted products,requiring surface coating for enhanced protection and performance. | |

| Galvalume aluminium-zinc coated (AZ) | Suitable for pre-painted steel and electronic cabinets. | |

| Surface Treatment | Chromium passivation (C) | Recommended for environments requiring high corrosion resistance. |

| Oiling (O) | Suitable to prevent oxidation during storage,transportation,and processing,ensuring product integrity and performance. | |

| Trivalent chromium passivation (C3) | Applied in environments requiring enhanced corrosion protection while adhering to environmentally friendly standards. | |

| Chrome-free passivation (C5) | Eco-friendly solution for areas with strict environmental requirements. | |

| Anti-fingerprint film (AF) | Designed for products where a clean,smudge-free surface is crucial,such as visible appliance panels. | |

| Classifications of Steel | Commercial quality (CQ) | Ideal for simple mechanical processing. Materials with thicknesses below 0.70mm can be used for mechanical interlocking processes,while those above 0.70mm are suitable for 90° bending. |

| Drawing quality (DQ) | Ideal for manufacturing products with basic shapes,making it suitable for mechanical interlocking processes. | |

| Structural quality (SQ) | Tailored for load-bearing applications,ensuring smooth curvature transitions during bending to enhance durability. |

Additional Note:

For applications involving complex forming or high-performance requirements, we advise thorough testing to ensure the selected product meets the necessary specifications.

- China’s largest private steel sheet manufacturer

- 48 production lines across 5 manufacturing facilities

- Annual capacity of up to 15 million tonnes, with 800,000 tonnes in stock

- E-mail:

- Mobile:

To get the quick quote, please specify the specification, grade, zinc layer thickness, surface with/ spangle pattern, coil inner diameter, coil weight, etc.

What types of businesses use galvanized steel products?

Galvanized steel products are used by a wide range of customers, including:

- Building material manufacturers

- Furniture manufacturers

- Automotive manufacturers

- Container manufacturers

- Metal product industries

- Transportation equipment manufacturers

- Product distributors

Can galvanized steel for architectural use meet wind resistance requirements for roofs and wall panels?

Do galvanized steel products for appliances feature special anti-bacterial or anti-corrosion treatments?

Can galvanized steel for automotive use meet OEM standards?

How is the compatibility between galvanized steel keels (C-channels) and lightweight partition walls?

What is the annual corrosion rate of aluminum-zinc coated steel (AZ150) in an environment with fertilizer dust?

What is the lifespan of outdoor galvanized steel products in humid or coastal environments?

The lifespan of outdoor galvanized steel in humid or coastal environments varies depending on the coating:

- Conventional Galvanized Steel (Z120-Z275): 8-15 years

- Zinc-Aluminum-Magnesium Coated (ZM): 20-30 years

- Aluminum-Zinc Coated (AZ): 25-35 years