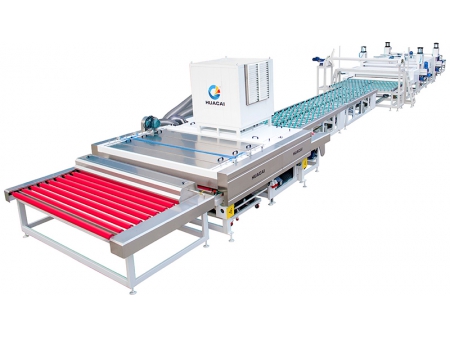

Curved and Flat Laminated Glass Line

Request a Quote

Technical Parameters

| Max. glass size | 6000×2440 mm |

| Min. glass size | 400×400 mm |

| Glass thickness | 6~80 mm |

| Glass length | 26200 mm |

| Power supply | AC380V 50HZ |

| Total power | 178 KW |

Equipment introduction

This flat glass laminating line is composed of the glass washing and drying machine, glass loading table, auto positioning device, automatic suction cup vacuum lifter, transition conveyer, PVB film laying machine (PVB film roll holder), glass heated roller press, etc.

- The QX2500C-LOW-E glass washing machine features a horizontal structure and consists of loading, washing, drying and unloading section, air blower, electric control cabinet, etc.

HP1600 auto positioning device

The auto positioning device features a horizontal design, made up of machine frame, positioning mechanism, transmission system, pneumatic system, electric control system, etc.- This suspended automatic suction cup vacuum lifter is used for transferring glasses, consisting of overhead crane (travelling track), pneumatic suction cups, vacuum system and electrical control system.

PVB roll holder

Three rolls of PVB films with different specifications can be loaded. The unwinding and rewinding of membranes are manually operated. The changeover of film roller is hoisting replacement.GD2500 transition conveyor

The transition conveyor utilizes horizontal frame construction and consists of machine frame, transmission system and electric control system.

The transition conveyor uses chain conveyor and the conveying speed is regulated by VFD and can be digitally displayed.- The glass heated roller press is comprised of the electrical cabinet and loading, pre-heating, pre-pressing, 1st heating, 2nd heating, 3rd heating, glass curving, roll pressing and unloading section.