Corrugating Rolls

Corrugating rolls have an important role in forming the fluted layer of corrugated boards. Their surface quality, hardness, and wear resistance directly affect the precision of flute shaping, the stability of bonding, and the overall output of the production line. In an era where profit margins run razor-thin, choosing the right corrugating rolls becomes a key factor in reducing maintenance costs and improving production efficiency.

At Yonghui, we focus on manufacturing corrugating rolls that support high-speed operation, extended service life, and reduced downtime. Our flute profiles are continuously optimized to meet evolving industry demands, including lightweight paper use and wider web widths.

Each corrugating roll we offer is designed to be compatible with major single facer models from manufacturers such as BHS, Fosber, Mitsubishi, BW Papersystems, Marquip, Peters, Isowa, JS, TCY, West River, Hsieh Hsu, K&H, XHL, Fuli, and Wanlian. Whether you need custom flute geometry or a specific surface coating, our team provides reliable corrugating roll solutions tailored to your production goals.

- Our corrugating rolls are built for performance in demanding production environments, combining proven materials with precision engineering and advanced surface treatment.

- We use 50CrMoA alloy steel, a material known for its stability under high-speed operation. Our corrugating rolls can run at speeds of over 350 meters per minute without compromising flute definition or cardboard quality.

- Backed by over 20 years of experience in flute profile design, we can design corrugating roll geometries that maintain consistent flute height and flute pitch, while optimizing paper usage. Our designs help reduce raw material consumption by 0.5% to 1%, offering a measurable cost advantage without affecting the board’s strength.

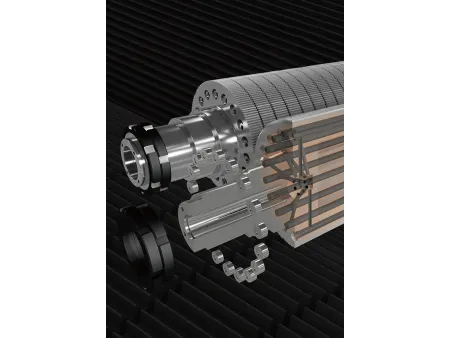

- Each roll undergoes a combined surface hardening process, which includes surface coating, nitriding, tempering, and cryogenic treatment. This results in a refined microstructure, stable surface hardness of HRC ≥ 60, and an extended service life. For peripheral heating corrugating rolls, life expectancy can exceed 100 million meters.

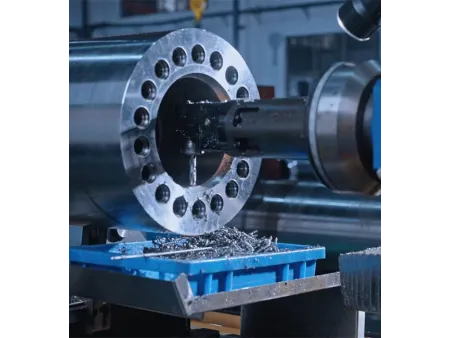

- To further enhance the quality of our corrugating rolls, we apply Praxair supersonic flame spraying technology and use Praxair 1342 tungsten carbide powder. This minimizes porosity and corrosion, while Siemens CNC grinders ensure precise flute accuracy. Our polishing process achieves a surface roughness of Ra 0.2–0.4, with a silicone oil coating added to prevent rust and pitting.

- We offer fast lead times and reliable support to help customers maintain efficient production with minimal downtime.

- We support our customers with a full range of services that help extend equipment life, simplify installation, and reduce downtime during maintenance and upgrades.

- We can repair worn or damaged corrugating rolls, glue rolls, pressure rolls, and doctor rolls, restoring them to working condition and reducing the need for new parts. Our team also offers flute profile design and drawing services tailored to specific production needs.

- For customers requiring specific finishes, we provide satin and engraved roller surfaces depending on the application. Bearing kits and component packages are available to make installation easier, and include options such as pre-lubricated bearing sets, cages, and housings.

- During inspections, we also offer welding and shaft journal repair to restore structural integrity. Various volume configurations can be supplied based on machine requirements, and our team can work with OEM drawings for equipment from BHS, Fosber, Langston, and others.

- To support efficient operation, we offer complete cartridge assembly services. This includes installing rolls, bearings, oil seals, and other accessories into preassembled units ready for use. Installation and commissioning can be done either on-site or remotely, depending on customer preference.

We offer complete roll refurbishment and retrofit solutions tailored for the corrugated packaging and printing sectors.

We focus on delivering high-quality customized solutions for corrugator machine components, tailored to meet the unique needs of our customers in corrugator rolls and corrugated board equipment.