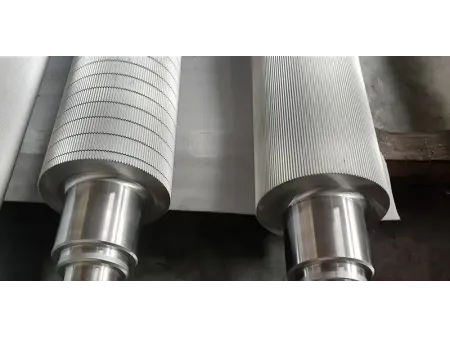

Chrome Plated Corrugating Rolls

Corrugated Machine Parts

Corrugating rolls with hard chrome coating used in corrugator machine for corrugated paper production

- Forged from high-strength 50CrMoA alloy steel for excellent structural integrity

- Finished with a hard chrome coating over 0.08 mm to improve wear resistance

| Flute Type | A | C | CB | B | BE | E | F | G | N | O |

| Flute Profile | UV | UV | UV | UV | UV | UV | UV | UV | UV | UV |

| Number of Flutes (Flutes/300mm) | 30±2 | 39±3 | 44±2 | 50±2 | 66±3 | 90±10 | 124±10 | 185±12 | 200±15 | 267 or designed |

| Flute Height | 4.6-4.9 | 3.6-3.9 | 3.0-3.5 | 2.6-2.9 | 1.9-2.1 | 1.1-1.5 | 0.7-0.8 | 0.5-0.65 | 0.4-0.5 | 0.25-0.35 |

| Take-Up Ratio (T.U.R) | 1.51-1.59 | 1.44-1.51 | 1.42-1.49 | 1.36-1.42 | 1.4-1.41 | 1.29-1.39 | 1.22-1.26 | 1.2-1.25 | 1.15 or designed | 1.14 or designed |

* Note: Flute types are customized based on the customer's requirements and the grammage range of liner and medium paper.

Our chrome plated corrugating rolls are manufactured from 50CrMoA alloy steel, then heat treated and precision-ground to ensure dimensional accuracy and structural strength. A hard chrome coating thicker than 0.08 mm is applied to the surface, creating a durable protective layer that significantly reduces friction at the flute tips. This improves wear resistance and helps maintain consistent flute geometry over time, extending the overall service life of the corrugating roll.

The resulting surface is smooth, bright, and resistant to wear, offering stable and reliable performance in standard-speed corrugated board production lines. To further support long-term use, we also provide regrinding and chrome recoating services, restoring worn rolls to working condition and helping customers reduce replacement frequency and overall maintenance costs.

Chrome plated corrugating rolls are suitable for producing a variety of corrugated board types, including A, B, C, E, F, and N flute profiles, in standard corrugated board production lines.

- Each flute profile is designed using computer-aided tools, offering solutions for A, B, C, E, F, and N flutes. Roll specifications such as diameter, length, flute height, and flutes per meter are precisely defined to ensure performance, durability, and production efficiency across a wide range of applications.

- Manufactured from premium 50CrMoA forged alloy steel, the roll body delivers high mechanical strength and structural stability, even under high-load operating conditions.

- Using advanced CNC grinding machines, we achieve a roundness tolerance within 10 μm, meeting international precision standards. Combined with our optimized flute designs, these rolls are engineered to support the speed, efficiency, and board quality requirements of modern corrugated production lines.

- A multi-stage heat treatment process is applied, including repeated stress relief and medium-frequency surface hardening, ensuring a surface hardness of HRC > 58 (HS 73–80) with uniform hardness across the entire roll and no soft zones.

Made from 50CrMoA forged alloy steel sourced from Zhongyuan Special Steel, a top-tier Chinese supplier. The material offers high strength, wear resistance, and thermal stability, ideal for high-speed corrugating applications.

- 50CrMoA forged alloy steel for strength and durability

- Corrugating roll body thickness ≥ 75 mm

Finished with hard chrome plating, with a coating thickness of 0.08–0.10 mm and a uniformity tolerance within ±0.01 mm to ensure consistent performance and wear resistance.

A composite treatment combining nitriding, quenching, tempering, and cryogenic cooling at –190 °C is applied to the roll surface. This process achieves a surface hardness of HRC ≥ 60, ensuring long-term durability and wear resistance.

- Combined heat treatment

- Nitriding

- Medium frequency quenching

Vacuum-sealed with anti-rust protection and packed in shock-resistant wooden crates, suitable for long-distance sea transport.

The quality control system includes 12 strict steps, covering every stage from raw materials to the finished product.

The process involves:

Raw material testing → weld air-tightness → dynamic balancing → hardness, flute profile and dimensions → pressure testing → coating thickness → final inspection.