Dough Divider

Dough Processing Equipment, Dough Production

The dough divider is utilized to separate and round dough into equal parts. Our dough dividers feature a simple design that makes it easy to clean and maintain. It can be used individually or in conjunction with a full baking line connected through conveyor belts. It provides a simple solution for large-scale producers of breads that can be packed with fruits and nuts like sweet bread, sandwich bread, toast, French bread, and more.

We offer 4 kinds of dough dividers include 1p dough dividers, 2p dough dividers, 3p dough dividers, and 4p dough dividers to shape large batches of dough into small dough balls. Different dough dividers alloy you to make different types of dough balls with varying weights and sizes to meet your production demands. The voltage of our equipment can be made compatible with your local power supply that varies by region. Feel free to browse the selection of our outstanding dough dividers to find the one that’s right for you.

Tips: Let the bulk dough stand no more than 10 minutes to ensure the weighing accuracy before it's divided and shaped. Dough going from 45% to 70% water content will rise better when divided.

| Type | YQ-1P | YQ-2P | YQ-3P | YQ-4P | YQ-5P |

| Power Supply | AC380V 50Hz | ||||

| Power | 1.6KW | ||||

| Capacity | 1900pcs/h | 3800pcs/h | 5700pcs/h | 7600pcs/h | 9500pcs/h |

| Dough Weight | 100-500g | 50-250g | 25-100g | 10-60g | 25-100g |

| Machine Weight | 480kg | ||||

| Machine Dimensions(L*H*W) | 880×1200×1500mm | ||||

- Hopper

The Teflon-coated stainless steel hopper is non-stick to assure a smooth infeed of the dough and facilitate easy daily cleaning. A PTFE-coated (polytetrafluoroethylene) hopper is also available upon request. Different hopper sizes can be customized based on your unique production requirements. Our custom hopper can provide a capacity of 40-80 kgs of flour per batch.

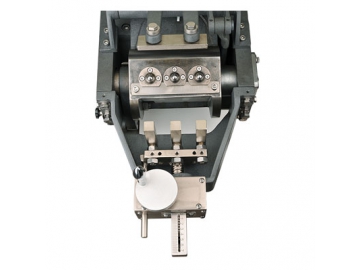

- Mold

We offer 1p dough dividers, 2p dough dividers, 3p dough dividers and 4p dough dividers to shape chunks of dough into small equal pieces. Our 4p dough dividers have the efficiency to divide bulk dough into 4 small equal dough balls. All of these molds are constructed using sturdy ductile cast iron with a hardness of 45 BHN, twice that of stainless steel with double heat treatments. Our burnishing technique produces a smooth and hardened surface to increase the reliability of the dough dividers. Different dividers allow you to create various types of dough balls with varying weight ranges and sizes.

- Control panel

1)User-friendly;

2)The number of divided dough pieces is automatically recorded;

3)Emergency stop with mechanical latching helps to avoid emergency situations.

4)The running speed of the dough dividers can be set according to your production requirements; -

Oil reservoirFood grade oil is stored in the oil reservoir and this makes the dough easier to stretch or sheet out. The divider oil pump can provide the proper amount of oil to the dough contacting the surface of the divider. You can choose the amount of lubricant at frequent intervals according to your own needs.

- Lift the protection guard to load the dough into the loading hopper

- Part of the dough is moved into the volumetric chamber by the main piston while a cutting blade separates it from the bulk of dough in the dough chamber.

- Dough is then divided in equal weight chunks by a linear displacement of the metric piston into the Metric Chamber. Then, the metric chamber descends and the metric piston pushes the dough pieces horizontally to the discharge conveyor belt.

- The dough capacity of the metric chamber can be adjusted on the metric piston based on the size of dough pieces desired.

- The double metric piston is offered as a spare part on demand. The single metric piston can be replaced with a double metric piston quickly and easily by the operator when needed.