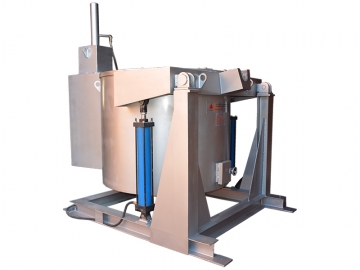

Regenerative Gas Fired Tilting Crucible Furnace

Request a Quote

Features

- Capacity: 800kg (customizable upon request)

- Melting rate: 280-300kg/h. The time it takes for a crucible full of aluminum to melt is about 4 hours.

- Process temperature: 680°C-800°C Energy consumption: the power of the burner is 400,000 kcal. About 80 cubic meters of natural gas are needed for melting one ton of aluminum.

- Air blower power: 4KW, 380V Motor power of hydraulic station: 2.2KW, 380V

- Total weight: about 6T

- Structure: furnace casing, furnace lining, combustion system, temperature control system, crucible nozzle, burner, oil cylinder, hydraulic station.

- Working principle: The tilting gas fired melting furnace features a crucible directly heated by natural gas burners. The furnace can be tilted by 90 degrees with an oil cylinder to pour out the molten aluminum.

Furnace structure

- External structure

1) Barrel casing made of 4mm thick steel plate

2) Crucible cover made of 25mm thick steel plate

3) Bottom plate made of 8mm thick steel plate

4) Cover made of 10mm thick steel plate

5) Chimney made of 6mm thick steel plate, can be flipped at 90 degrees

6) Heat exchanger made of 6mm thick 304 stainless steel - Construction materials of furnace lining

1) Three layers of high temperature insulation boards (with the density of 400)-aluminum silicate fiber 1140 semi-rigid board -LYGX-154HB

2) Insulated cotton with the density of 260-ceramic fiber blanket

3) Heat-resistant insulation brick and castable-RFTC MD 60A

Crucible

- One-shot silicon carbide graphite crucible with nozzle

- Proper operation

1)The crucible must be pre-heated. The first phase of low heat is to dry the crucible, the second phase of high heat is the change the physical property of the glaze in the surface of crucible to better protect the crucible and prolong its service life.

2)The inner wall of the crucible can be coated with a coating agent at first use to prevent molten aluminum from sticking.

3)Correct feeding method: dropping off the aluminum ingot vertically rather than obliquely along the wall of crucible. Avoid large impacts within the crucible.

4)Before shutting down the furnace, the aluminum ingot in the crucible should be cleared to prevent damage to crucible caused by the thermal expansion and contraction of remaining aluminum.

5)The warranty period of the crucible is 3 months. The normal service time is about 6 months. Lift the crucible after use for one month to change the position directly facing the natural gas inlet.

- Hydraulic station

- Safety protection device

The electronic control system of tilting gas fired crucible furnace is equipped with automatic alarm systems including an over-heating alarm and material leakage alarm to guarantee production safety.

Installation, debugging and transportation

We are responsible for the transportation of equipment to the customer’s factory, the installation, and operation training of equipment, with the exception of hoisting expenses incurred by unloading and placing the equipment in place.

Delivery and quality guarantee

- Delivery: Deliver the equipment within 30 working days after signing the contract.

- Quality guarantee: Our equipment is covered under a one-year warranty that begins once the equipment is debugged. Free repair and replacement services will be provided during the period with the exception of consumables or damage caused by faulty operation.