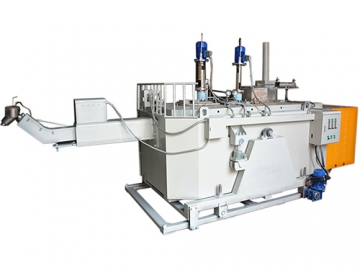

Regenerative Magnesium Melting Furnaces-Gas Fired

Request a Quote

Gas fired magnesium melting furnace

- A3 steel plate and profile steel is used for the casing of the furnace.

- The insulation layer is composed of high-quality Nano-plate, insulation material and calcium silicate board, which are laid in the outer enclosure.

- The furnace lining is made from heat-resistant insulation brick.

- German KromSchroder burner.

- Liquid leakage alarm with an electrode connected to the alarm system of the electric furnace control cabinet. Furnace will shut down if the alarm is triggered.

- The protective-gas system should be turned on until the temperature of the molten magnesium drops below 350 degrees. The crucible should not be lifted out for maintenance until the molten magnesium is cooled to a solid state naturally.

- The height of the furnace can be customized according to your production needs and factory layout.

Thermal energy storage devices

- 6mm thick welded 304 stainless steel plate and stainless steel pipe.

- Heat energy is recovered instead of exhausted into the air to heat the crucible. This saves energy by 15-20%

- Effectively reduces the ambient temperature of the production plant.

Crucible

- The crucible is made of bimetal composite material with a total thickness of 25mm or 31mm.

- The outer layer is made of imported high-quality heat-resistant 310S stainless steel plate with a thickness of 3mm, and the inside is made of Q345R stainless steel plate with a thickness of 22mm or 28mm, to ensure the overall strength of the crucible.

- The two ends of the crucible are mechanically bended forming a seamless shape, ensuring the crucible can be rotated and heated evenly.

- The crucible is easy to maintain and replace if needed. Its average service life is more than 2 years.

- The whole crucible is coated with boron nitride for protection.

- The crucible is made of two separated chambers, a melting chamber and a holding chamber to ensure the purity of molten magnesium.

- The gas is evenly distributed in the crucible.

- The cover and the crucible are locked by stainless steel screws, which are resistant to high temperature, not easily deformed, and easy to disassemble. Insulation material and high temperature rope are pressed in the middle to effectively prevent air leakage.

Parameters

| Model | HX-500 | HX-800 | HX-1000 |

| Model of adaptive die-casting machine | 400T-500T | 630T-800T | 800T-1000T |

| Furnace dimensions | 3941 * 1909 * 1203 | 4986 * 2092 * 1860 | 5341 * 2092 * 1860 |

| Crucible capacity | 500kg | 800kg | 1000kg |

| Crucible material | 310S+Q345R | 310S+Q345R | 310S+Q345R |

| Crucible thickness | 3mm+22mm=25mm | 3mm+22mm=25mm | 3mm+28mm=31mm |

| Crucible structure | double chamber, double pump | double chamber, double pump | double chamber, double pump |

| Max. Melting rate | 160kg/h -180kg/h | 260kg/h -280kg/h | 330kg/h -350kg/h |

| Power supply | AC380V (customizable) | AC380V (customizable) | AC380V (customizable) |

| Burner system power | 300,000kcal | 400,000kcal | 500,000kcal |

| Vent fans power | 4.5KW | 5.5KW | 5.5KW |

| Heat recovery from exhaust gas | continuous heat transfer system | continuous heat transfer system | continuous heat transfer system |

| Flue gas temperature | ≥250℃ | ≥250℃ | ≥250℃ |

| Temperature rise in the external surface of melt | <40℃ | <40℃ | <40℃ |

| Max. Allowable temperature of magnesium liquid | 720℃ | 720℃ | 720℃ |

| Melting loss of magnesium melt | <1.2% | <1.2% | <1.2% |

| Energy consumption per ton of magnesium | fuel gas: 80~85m3/ton | fuel gas: 80~85m3/ton | fuel gas: 80~85m3/ton |

| Temperature control precision of magnesium liquid in pouring ladle | ±3℃ | ±3℃ | ±3℃ |

| Furnace noise factor | <80 dB | <80 dB | <80 dB |

| Furnace overheat protection | furnace temperature≦900℃, magnesium liquid ≦720℃ | furnace temperature≦900℃, magnesium liquid ≦720℃ | furnace temperature≦900℃, magnesium liquid ≦720℃ |

| Heating power of depositing | <3.0 kW | <3.0 kW | <3.0 kW |

| Proportioning range | 0.05~5kg | 0.05~10kg | 0.05~15kg |

| Starting temperature of automatic gas supply | 350 ℃ (adjustable) | 350 ℃ (adjustable) | 350 ℃ (adjustable) |

| Airflow | 3~15 l/m (adjustable) | 3~20 l/m (adjustable) | 3~25 l/m (adjustable) |

| Protective gas | SF6/R134a+N2 | SF6/R134a+N2 | SF6/R134a+N2 |

| Gas supply accuracy | ±1‰ | ±1‰ | ±1‰ |

| Drive mode | gear motor | gear motor | gear motor |

| Preheating mode | up and down radiant heating | up and down radiant heating | up and down radiant heating |

| Max. Electric power | 28 kW | 28 kW | 28 kW |

| Feeding mode of magnesium ingot | by manipulator | by manipulator | by manipulator |