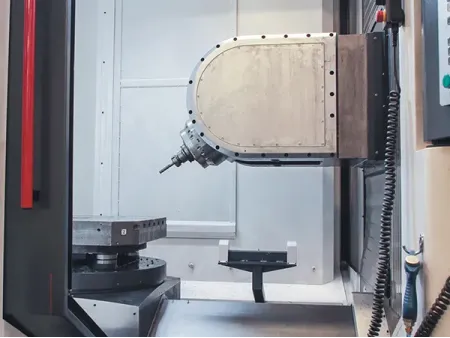

5-Axis Machining Center with Fork Milling Head

5-axis machining centers with a fork-type milling head use a T-shaped structure: the column moves on the X axis, the spindle head travels vertically on the Y axis and the table advances along the Z axis. A vertical-table option is available when the part needs an upright setup. The fork-type milling head rotates continuously, giving access to angled surfaces and multiple faces in one setup. Rotary positioning can be handled by a high-precision worm-gear table, a torque-motor direct-drive table for quicker motion, or a direct-drive milling-and-turning table when both operations are required in one setup.

These 5-axis machining centers operate on the X, Y, Z, A and B axes, allowing full five-axis simultaneous machining. The configuration suits a wide range of complex parts in aerospace, automotive, marine, energy and mold applications. Depending on production needs, the spindle can be equipped with speeds of 10000, 12000 or 15000 rpm, giving flexibility for different materials and cutting conditions.

| Model | | | | |

| Worktable size (mm) | Ø800 /800×800 | Ø1000 /1000×1000 | Ø1250 /1250×1250 | Ø1600 /Ø1800/Ø2000 |

| Max. worktable load capacity (kg) | 2000 | 2500 | 2500 | 8000 |

| X-axis travel (mm) | 1200/1400 | 1600 | 1600 | 2100 |

| Y-axis travel (mm) | 1000/1200/1400 | 1000/1200/1400 | 1000/1200/1400 | 1250/1600 |

| Z-axis travel (mm) | 1100/1400 | 1600 | 1600 | 2100/1950 |

| A-axis rotation range (°) | -120 to 30 | -120 to 30 | -120 to 30 | -120 to 30 |

| B-axis swing range (°) | n×360 | n×360 | n×360 | n×360 |

| Spindle speed (r/min) | 20–7000 | 20–7000 | 20–7000 | 20–7000 |

| Positioning accuracy (X/Y/Z) (mm) | 0.008 | 0.008 | 0.008 | 0.008 |

| Repeatability (X/Y/Z) (mm) | 0.004 | 0.004 | 0.004 | 0.004 |

| A-axis positioning accuracy (″) | 8 | 8 | 8 | 8 |

| A-axis repeat positioning accuracy (″) | 4 | 4 | 4 | 4 |

| B-axis positioning accuracy (″) | 8 | 8 | 8 | 8 |

| B-axis repeat positioning accuracy (″) | 4 | 4 | 4 | 4 |

The base, column and saddle are cast from high-grade iron to keep the structure rigid and stable. The column is built as a single frame, which helps control heat deformation during long machining cycles and keeps the geometry steady. This layout provides a solid foundation for accurate cutting, especially when working with complex shapes.

The X, Y, and Z feed axes use servo motors together with linear roller guides and precision-grade ball screws. This combination gives the drives the rigidity and accuracy needed for stable positioning during machining.

The spindle uses a U-type tilting head, allowing it to swing along the A axis. The A axis uses a hydraulic locking mechanism that holds the tilting head steady during heavy-cutting operations. The spindle reaches a maximum speed of 4000 r/min.

Can these 5-axis machining centers finish complex mold surfaces in a single setup?

The five-axis movement lets the tool reach angles and surfaces that a three-axis setup simply can’t access. With accurate positioning and a steady clamping setup, the center can cover areas that would normally become blind spots, so cavities and curved surfaces can be finished in one setup without having to reposition the part.

Do the spindle speed and torque options cover different grades of mold steel?

Yes. The series supports both low-speed, high-torque mechanical spindles and high-speed motor spindles, including 8,000 rpm and 12,000 rpm variants. Combined with full five-axis linkage on X, Y, Z, A and B, these configurations meet the cutting requirements of most mold steels, from tougher grades that need stronger torque to materials that benefit from higher spindle speeds.