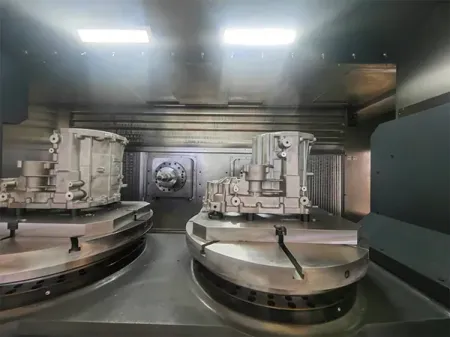

5-Axis Machining Center with Dual Spindle

Five-axis machining centers with dual spindles and dual rotary tables are designed for high-precision and high-throughput work. Linear-motor drives and a full closed-loop CNC system help keep the positioning stable even at higher speeds. They are widely used for aluminum-alloy components in new-energy vehicles and aerospace production, since the dual-spindle and dual-rotary-table arrangement helps keep the surface finish cleaner, the dimensions more stable, and the machining time shorter.

- X/Y/Z travel: 800 / 1000 / 650 mm

- A/C rotation: ±110° / n×360°

- X/Y/Z rapid speed: up to 100 m/min, with acceleration of 10 m/s²

- A/C maximum rotation speed: 40 r/min

- Spindle maximum speed: 14,000 r/min

- Tool magazine: 64 tools, with tool-change time (cut-to-cut) of approx. 4.5s

| Model | | |

| Worktable size (mm) | 2×Ø630 | Ø800 |

| Max. worktable load capacity (kg) | 2x600 | 800 |

| Max. swing diameter (mm) | 2×Ø795 | Ø1600 |

| Number of worktables (pcs) | 2 | 1 |

| X/Y/Z-axis travel (mm) | 800/1000/650 | 1500 /1000/650 |

| X/Y/Z-axis rapid traverse speed (m/min) | 100 | 100 |

| X/Y/Z-axis acceleration (m/s²) | 10 | 10 |

| A/C-axis travel (°) | 110/360 | 110/360 |

| A/C-axis rotation speed (r/min) | 40 | 40 |

| Max. spindle speed (r/min) | 14000 | 10000 |

| Spindle power (S1/S6) (kW) | 37.5/80 | 54/67.5 |

| Spindle torque (S1/S6) (N·m) | 90/150 | 200/240 |

| Number of spindles (pcs) | 2 | 1 |

| Tool interface | HSK-A63 | HSK-A100 |

| Tool magazine capacity (tools) | 64 | 48 |

| Max. tool diameter / with adjacent pocket empty (mm) | 80/160 | 125/200 |

| Max. tool length (mm) | 300 | 500 |

| Max. tool weight (kg) | 8 | 20 |

| Tool change time (cut-to-cut) (s) | 4.5 | 4.5 |

| X/Y/Z-axis positioning accuracy (mm) | 0.005 | 0.008 |

| X/Y/Z-axis repeatability (mm) | 0.003 | 0.004 |

| A/C-axis positioning accuracy (″) | 5 | 5 |

| A/C-axis repeat positioning accuracy (″) | 3 | 3 |

The X/Y/Z axis units use a box-in-box layout made from welded high-strength steel plates. This gives the structure good rigidity while keeping the moving parts lighter and easier to control.

The bed and column form a single frame-type structure that gives the machine a very stable base, something that directly supports both high-speed cutting and tight-tolerance work. On the linear axes, positioning accuracy reaches 0.005 mm, with 0.003 mm repeatability. For the rotary axes, positioning accuracy is 5 arc-seconds, with 3 arc-seconds repeatability.

The Z1/Z2 spindle axes and C1/C2 rotary tables use torque-motor drives. The A1/A2 axes run with synchronized dual torque motors, and the C1/C2 axes are directly driven. Each rotary axis uses a booster clamp and a mechanical lock to keep the rotation firm, the positioning steady and the cutting process stable.

The linear motors run without mechanical contact, so there is no wear or backlash. The linear-motor system lets the axes reach high speeds while keeping both the positioning and the motion steady.