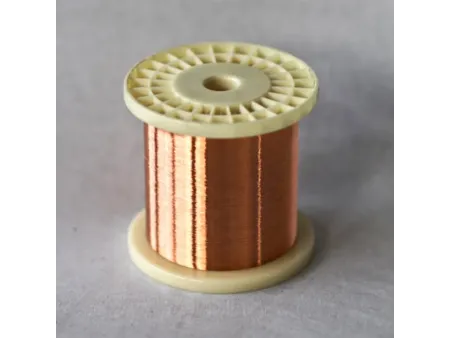

Oxygen Free Copper Wire (OFC)

Purity level exceeding 99.97%

Copper Conductor

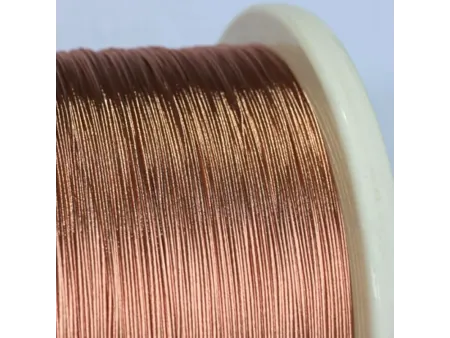

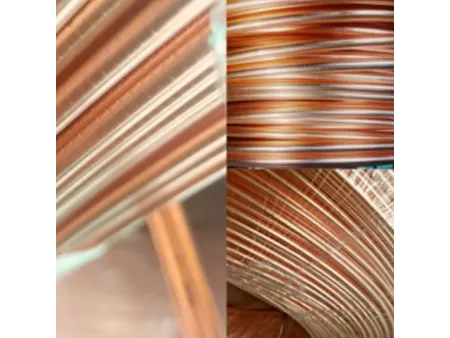

Oxygen-free copper wire (OFC) is a high-purity material ideal for applications that require efficient conductivity and reliability. We offer two grades to suit different production needs: No. 1 oxygen-free copper (CU > 99.97%) and No. 2 oxygen-free copper (CU > 99.95%). These wires are available in diameters ranging from 0.02mm to 2.0mm and come in various configurations, including single wire, stranded wire, multi-strand wire ropes, and parallel multi-wires. To manufacture quality OFC wires, several processes are involved, including drawing, annealing, stranding, electroplating, and insulation. The high purity and precise processing of these wires ensure optimal performance in electrical and communication systems, making them a preferred choice for demanding applications.

- Used in electrical wires, cables, and electronic components such as printed circuit boards.

- Suitable for windings in electrical equipment, including generators and transformers.

| Conductor Material | Category | Purity | Oxygen Content | Impurity Content | Wire Diameter |

| Oxygen Free Copper | No. 1 Oxygen Free Copper | 99.97% | ≤0.003% | ≤0.03% | 0.02-8.0mm |

| Oxygen Free Copper | No. 2 Oxygen Free Copper | 99.95% | ≤0.005% | ≤0.05% |

| Wire Drawing | Wire Stranding/Multi-Wire Processing | Wire Plating |

| Can be drawn down to 0.02mm | Stranded Wires, Parallel Multi Wires | Bare Wire, Tin Plating, Silver Plating, Nickel Plating, Copper Plating Enameling: Polyurethane QA(UEW), 155/180℃ Polyester QZ(PEW), 130/155℃ Polyesterimide QZY(EIW), 180℃ Polyamideimide QXY(AIW), 200/220℃ |

- Ensures stable performance with effective heat dissipation due to its high thermal conductivity.

- Easily shaped into wires, rods, or tubes, providing versatility for various manufacturing processes.

- Resists corrosion in standard environmental conditions thanks to its high purity and minimal impurities.

- Supports advanced applications with diameters starting at 0.02mm and multi-strand designs, offering enhanced flexibility and bending resistance.