Plastic Thermoforming Machine (PP/PET/PS/PVC)

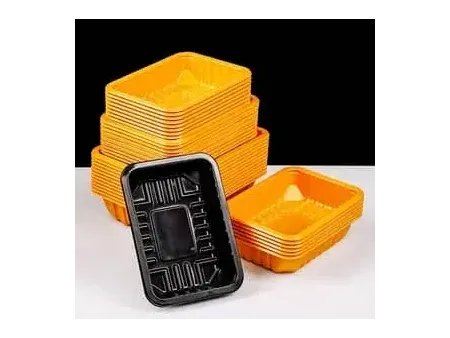

This plastic thermoforming machine can process PP, HIPS, PS, PVC, and PET sheets into a wide variety of shapes, including circular, square, and irregular designs. It is ideal for manufacturing packaging products such as boxes, plates, trays, bowls, lids, and more. Applications cover food packaging, industrial packaging, and cosmetic packaging, making it a versatile solution for different sectors.

| Model | | |

| Max. forming area | 760×540mm | |

| Max. forming depth | 100mm (pick product from inside the mold) | |

| 120mm (pick product from outside the mold) | ||

| Sheet thickness | 0.2-1.5mm | |

| Production speed | 600-1500cycles/hr | |

| Heating power | 132kW | |

| Motor power | 33kW | |

| Air pressure | 0.7MPa | |

| Air consumption | 3000 liters/min | |

| Water consumption | 70 liters/min | |

| Power supply | 3 phase, AC 380±15V, 50Hz | |

| Sheet roll diameter | 1000mm | |

| Machine weight | 9000kg | |

| Dimensions (L×W×H) | Main machine | 6500x2020x2400mm |

| Material feeder | 1500×1420×1450mm | |

- Feeding rack

- Material feed platform

- Sheet conveyer track

- Upper heating oven

- Lower heating oven

- Touchscreen control panel

- Forming and cutting station

- Stacking robot

- Vacuum tank

- Air storage tank

- Finished product conveyor belt

- Scrap rewinder

-

- 1

Material feeding, heating, forming, cutting, and stacking integrated in one machine

-

- 2

You can choose the in mold grasping method to ensure that there are no hanging points around the product and improve the product quality standards

-

- 3

Forming and punching in the same workstation, simplifying operation and improving accuracy

-

- 4

Servo control system ensures smooth, stable, and consistent performance

-

- 5

In-mold cutting delivers precise punching with zero error, ideal for pure PP products

-

- 6

High material utilization, with low air consumption and reduced maintenance needs

-

- 7

Stable capacity, making the machine suitable for continuous, large-volume production

-

- 8

User-friendly PLC touchscreen for easy operation and control

-

- Motor and driver

-

- Electrical component

-

- Vacuum pump

-

- Control valve

-

- User-friendly touchscreen for full machine control

- Large memory with strong data storage capacity

- Customizable operating language

HMI Touchscreen -

- Automatic loading system driven by motor

- Positive and stable sheet feeding

- Max. feeding roll diameter of 1000mm

- The feeding roll weight of 100-500kg

Material loading -

- Upper and lower ovens made of 304 stainless steel

- Equipped with infrared ceramic heaters for efficient heating

- Oven movement controlled by air cylinder

- Independent heating zones for precise temperature control

- Operation can be started after 5-min heating

Heating system -

- Forming table size of 540×760mm

- Max. forming height of 120mm

- Forming and cutting carried out at the same workstation

- Mold opening and closing controlled by servo motor system

Forming station -

- Upper and lower drive system provides positive and negative pressure for stable molding;

- Forming and punching integrated into one process for precise, error-free results;

- The mold with good cooling can result in good forming;

- Adopting high-precision laser cutting, easy to replace and cost-effective;

Mold -

- Conveyor platform size: 1200 × 600 mm

- Simplifies sorting and handling of finished products

Conveyor Belt -

- This stacking machine has two stacking modes: In mold grasping and external grasping

- The in mold grasping method can avoid hanging points at the edges of the product

- External grasping can better improve the operating speed of the machine

- Servo-driven stacking system

- Conveyor belt is removable and replaceable for easy maintenance

Stacking station - This stacking machine has two stacking modes: In mold grasping and external grasping

-

- Electrical components are from Inovance, Panasonic, Schneider, Festo Mac etc.

- Includes emergency stop button for safety

- Optimized electrical design for stable and reliable machine operation

Electrical cabinet