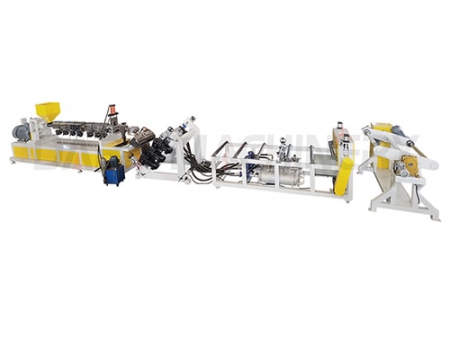

PP/PS/PE Plastic Sheet Extrusion Machine, DB-110-850

Plastic extrusion line for making plastic sheets and plates

Get ready to experience smooth and efficient plastic sheet production with our PP/PS/PE plastic sheet extrusion machine. Designed for thermoforming, vacuum forming, and stationery-use sheets, this machine is your go-to solution for creating high-quality polystyrene (PS) and polypropylene (PP/HIPS) sheets. Perfect for manufacturing plastic cups, bowls, trays, blister packaging, and more. Reach out today to see how this reliable machine can elevate your production line.

PP, PS, PE, HIPS

Ideal for producing high-quality plastic products such as cups, bowls, trays, blister packaging, and stationery-use sheets through thermoforming and vacuum forming processes.

| Motor power | 55 kW |

| Screw diameter | Ø110 mm |

| L/D ratio | 33:1 |

| Screw speed | 80 rpm |

| Effective sheet width | 780 mm |

| Sheet thickness | 0.2-2mm |

| Sheet width range | 400-800 mm |

| Production capacity | 150-250 kg/h |

| Heating zone | 7 rows |

| Heating power | 50 kW |

This plastic sheet extrusion machine consists of seven main parts: extruder, filter, die head, roller, traction unit, winding unit, and edge trimming system.

- Extruder Barrel and Heaters

Equipped with segmented protective heater covers to maintain stable temperature during operations.

- Die Head Component

- Sheet Width: 400-800 mm

- Built with high-quality P20 mold steel for enhanced durability.

- Three-Roll Calender Rollers

- Roller Diameter: 300 mm

- Roller Length: 900 mm (Effective Width: 400-800 mm)

- Number of Rollers: 3

- Roller Linear Speed: 0-13 m/min

- Drive Motor: 3.0kW × 3 (independently controlled)