SJ-403-1 (gasket width 5-30mm) Polyurethane Foam-in-Place Gasketing Machine

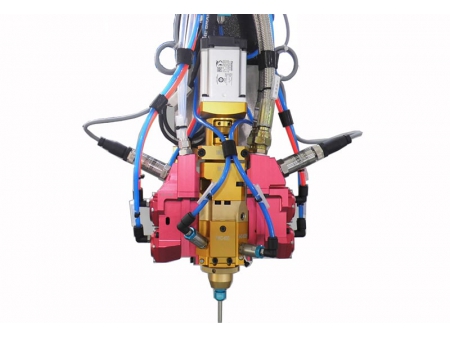

The self-engineered SJ-403-1 polyurethane foam-in-place gasketing machine features a more compact interior and boasts an instant nozzle-closing mechanism to prevent material drips and blockages, alongside automated cleaning and pressure control functionalities. Its mixing chamber features independent modules, which simplify maintenance and minimize reliance on quick-wear parts.

- Application rate 0.3-5g/s

- Gasket width 5-30mm

- Travel speed 0-30 m/min

The automatic polyurethane foam-in-place gasketing machine can be applied to auto parts, metallic enclosures, energy storage system, electronic devices, home appliances, cooling systems, air cleaners, etc.

| Travel Range (X/Y/Z) | 2250×1250×200mm (customizable) |

| Dimensions | 2700×2200×2200mm (customizable) |

| Weight | 1600kg |

| Gasket Width | 5-30mm (adjustable within the range) |

| Mixing Ratio | 1:1-10:1 |

| Working Temperature | -15°C to 35°C |

| Metering Accuracy | ±0.2% |

| Pressure Limit & Alarm | 0-4Mpa |

| Filtration Accuracy | 40-50µm |

| Application Rate | 0.6-5g/s |

| Travel Speed | 0-12m/min |

| Repeat Accuracy | ±0.06mm |

| Air Pressure | ≧0.4Mpa |

| Total Power | 3-4kW |

| Frequency | 50HZ |

| Voltage | Three-phase five-wire 380V |

- A linear robot with an intelligent control system switches freely between 2D and 3D mode.

- CNC multi-axis programming enables the two-component mixing and dosing system to achieve complex operations.

- Intelligent parameter storage allows for flexible movement paths.

- Intelligent verification of the density of foam gaskets, accurate modification of foam gasket viscosity, and support for various foam gasket brands for optimal performance.

- Customizable ports tailored to specific operational requirements.

- Compatible with Industry 4.0 MESTIntel and other systems.

- Intelligent control system allows processing of both 2D and 3D components. Enhanced by CNC multi-axis programming, the formed-in-place gasket machine is able to perform flexibly along any paths.

- Intelligent operation simulation eliminates inaccuracies due to human measurement errors.

- DSP chip from American TI Korea-sourced ARM chip as the master control CPU FPGA chip from American ALTERA.

- Dual-core setup can be integrated within the control cabinet or positioned externally as an independent component.

- Automatic image generation for 2D products without the need for programming. Images of 3D products can be exported via USB flash drive.

- A self-developed, high-precision mixing valve (MKC-600) achieves remarkable dosing accuracy of 0.01g/s for one-component materials.

- A mixing chamber designed with adjustable pressure settings and alarm systems to counteract pressure fluctuations due to environmental factors, ensuring stable operation.

- Mechanic and pneumatic controls for smooth dispensing of consistently shaped foam gaskets, preventing accumulation or inconsistency.

- A patented, high-pressure cleaning system for the mixing chamber, utilizing turbocharged streams through four holes to achieve superior cleaning effect.

Sourced from the German manufacturer Barmag, the gear metering pump ensures precise dispensing with a metering accuracy of ±2%.

- Six Panasonic servo drives from Japan. Each operates independently to guarantee stability and precision, providing a stable, efficient, and noise-free operation.

- A high-precision reduction drive achieves accurate repositioning.

- A gear rack incorporated along the guide rail to improve speed and minimize vibration at corners.

The water-cooled storage tank features a two-layered construction using 316 stainless steel, automated stirring functionality to maintain material consistency, advanced monitoring of the material's gas content, automatic air filling, an integrated underload alarm to maintain consistent material levels, automated foam gasket filling for seamless production, sophisticated temperature control that operates efficiently without the need for an external air conditioning device, offering convenience and reducing space requirements.

- A linear robot.

- A control system (electrical cabinet included).

- A water-cooled storage tank.

- An aluminum alloy workbench.

Two component polyurethane

- The foam gaskets get foamed directly on the applied product surface. The foam-in-place gasketing machine dispenses a soft, elastic foam gasket, ensuring adaptability and durability in various applications.

- Made of polyurethane, the foam gasket is a mixture of two essential components: polyol (component A) and isocyanate (component B). The foam gasket can achieve its final state within minutes.

- Width/height ratio: 2:1-3:1

- Curing time: 10-20 minutes

- Dust-free and wind-protected environment

- Humidity: 40-70%

- Temperature: -15°- 35°