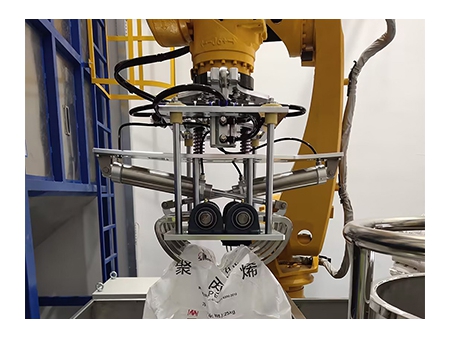

Robotic Bag Emptying Machine

Designed for depalletizing, bag opening and emptying, empty bag compaction and disposal, conveying, and dust removal of raw material bags, our robotic bag emptying machine is a totally automated, intelligent, integrated system. This method calls for no manual operation, beyond only pallet stacking. The bags are lifted by the robotic arm to the cutting device, where they are perforated releasing the content into a storage tank. The arm then shakes the empty bags to guarantee thorough discharge, therefore allowing a dust-free, automatic emptying mechanism.

For effective bag emptying, crushing, and feeding activities, this robotic system has extensive application in sectors including chemicals, building materials, feed and fertilizers, plastic materials and other industries.

- Capacity: 150-250 bags per hour

- Bag weight: 2.5-50kg

- Material residue: Approximately 0.1%

- Stack size: 2100×1400×1300mm

- Operation mode: Continuous bag opening

- Bag size & material: Customized as per customer requirments

- Improved Working Environment: Reduces dust exposure, enhancing worker health and safety.

- High Automation: Significantly increases production efficiency.

- Reliable Operation: Low power consumption with minimal maintenance and repair costs.

- Strong Flexibility: Customized solutions tailored to various customer conditions.

- Explosive Atmosphere Compatibility: Suitable for automated operations in hazardous environments.