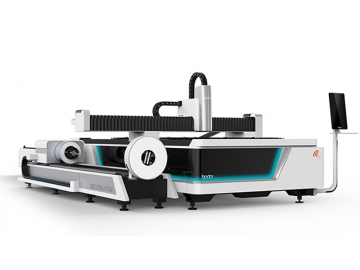

All Cover Dual-Use Laser Cutting Machine P-T

- Sheet metal processing

- Aerospace

- Electronic product

- Auto parts

- Machinery Parts

- Lamp

- Household appliances

- Stainless steel

- Alloy steel

- Carbon steel

- Aluminum alloy

- Galvanized steel

- Copper

- Titanium

| Model | P3015T | ||

| Working area | 3000mm*1500mm | ||

| Laser output power | 4000w/3000w/2000w/1500w/1000w | ||

| Effective pipe cutting diameter | Φ20- Φ200mm | ||

| Effective square tube cutting diameter | □20*20-□140*140mm | ||

| Rectangular tube | Min. edge length | ≥20mm | |

| Max. outer circle diameter | ≤200mm | ||

| Effective pipe cutting length | 3m/6m | ||

| X/Y/U-axis positioning accuracy | 0.03mm | ||

| X/Y/U-axis repositioning accuracy | 0.02mm | ||

| X/Y-axis max. speed | 100m/min | ||

| U-axis max. moving speed | 30m/min | ||

- Cast iron bed

The bed of this machine is made from flake graphite cast iron with a tensile strength of 200MPa. The material is chosen because of its high compressive strength and hardness, ensuring excellent stability and wear resistance. The laser cutting machine will always maintain high precision.

- Cast aluminum crossbeam

The crossbeam of the laser cutter is produced using lightweight and rigid aluminum. Each crossbeam is processed with integral steel mold pressure casting and will undergo artificial aging, solution treatment, and finishing to improve its rigidity, surface quality, and ductility. The crossbeam is perfect for adapting to the high speed movements during processing.

- Exchange Platform

The automatic exchange platform system enables rapid exchanging between the two exchange platform to significantly enhance the working efficiency of the laser cutter. The rack and pinion transmission system delivers improved rigidity and operating accuracy. This reduces feeding time and maximizes efficiency.

- Automatic nozzle changer

The automatic nozzle changer features an accurate control system to replace nozzles according to different materials and thicknesses automatically, eliminating the need for time costly manual replacement. The system also enables automatic calibration and cleaning functions. The high-precision drive system provides reliable replacement precision and stability. The fully enclosed device maximizes operator safety.

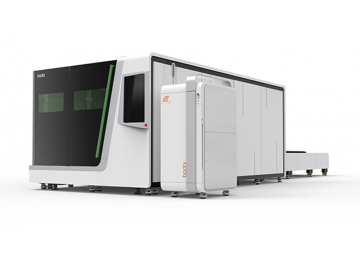

- Full protection cover

The laser cutting equipment is fully enclosed, preventing dust and eliminating light pollution during processing. Its intelligent monitoring system significantly reduces the failure rate, resulting in a safer, cleaner working environment.

- Self-centering chuck

Due to the machine’s automatic electric chuck and claw DC motor drive, the clamping motor current is adjustable and stable, giving it a wider clamping range with greater force. It carries out non-destructive pipe clamping and automatic centering and clamping of the pipe. The chuck features a smaller size with low rotation inertia and strong dynamic performance.

- Optional automatic material loading device (iLoader)

iLoader – the automatic loading device increases processing efficiency by up to 80% compared to manual operation. The swing arm position is controlled with outstanding precision and it allows a rotation of 120° for greater flexibility when paired with the equipment. A safety sensor module is equipped to prevent any accidents.

- Bodor Pro 2.0 operation system

The operating system of the automatic laser cutter produces an intelligent layout for graphics cutting and supports the importing of multiple graphics, optimizing performance. The control system provides an intuitive operating experience, enhancing the utilization of the workpieces and ultimately reducing waste and saving money.

- Auxiliary gas low pressure alarm function

The system will sound an alarm if the pressure is lower than the optimal level for cutting and precision. This helps the operator to ensure cutting performance with greater accuracy through timely gas replacement.

- Auxiliary feeding mechanism

Raising and lowering the subsidiary roller table reduces the friction between parts and the working table. This facilitates more convenient loading and unloading.

- Intelligent travel protection

This allows operators to automatically monitor the operation range of the crossbeam and cutting parts. This greatly improves the equipment performance and safety of the users.

- Automatic lubrication system

This system provides the necessary lubrication oil for the equipment at predetermined times and volumes to maintain high performance and safety. It will alarm if any abnormalities or low liquid levels are detected. The system greatly enhances cutting precision and maximizes the service life of the machine.

- A new generation of safety guidance module

This device ensures the laser head maintains a safe distance from the workpiece to prevent collision. If contact is made, the machine will automatically stop to protect valuable components. The module minimizes the failure rate and improves cutting performance.

- Intelligent alarm system

In the case of any abnormality, the system will sound an alarm that will be displayed through the control center. This will help operators quickly find the cause of the problem and minimize downtime.

- WIFI remote intelligent assistance

Real-time feedback anywhere, including fault analysis and troubleshooting operations.