Labeling Machine for Mobile Phone Accessories

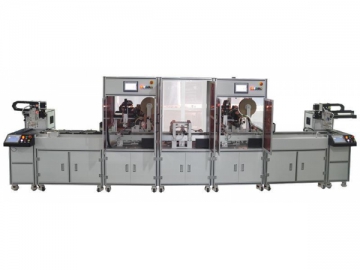

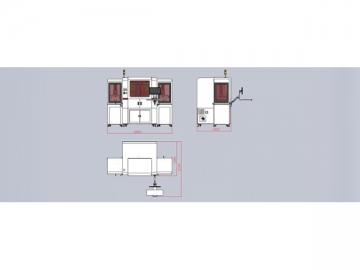

Newly developed, the fully-automatic mobile phone accessories labeling machine only demands one operator, far fewer than 20 operators for traditional labeling equipment. Characterized by high efficiency, stable properties, small occupation area and multiple stations, the labeling system realizes a process speed of 1,500 pieces every hour. It's well suited for cellphone manufacturers who want to reduce cost, save labors and improve production.

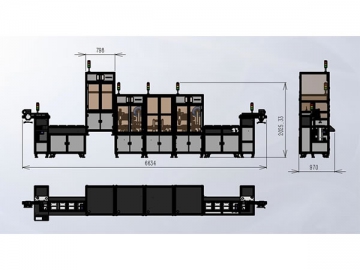

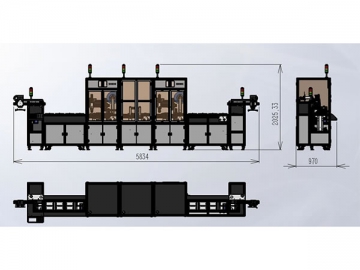

Specifications of Mobile Phone Accessories Labeling Machine| Items | Parameters | Notes |

| Size of single station | L 600mm×W 1600mm×H 1900mm | |

| Number of stations | 8 stations | The station number can be designed upon request. |

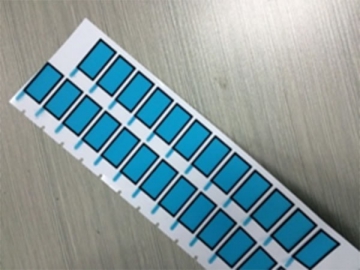

| Labeling range | L150mm×W150mm | |

| Cellphone cover size | Max: L160mm×W80mm Min: L135mm×W60mm | |

| Size of accessories to be sucked | Max: 50×70 mm Min: 3×3 mm | |

| Basic process line (cellphone cover) | Automatic material feeding-cellphone front cover-cellphone back cover-cover discharging | |

| Feeding and discharging | Fully-automatic | |

| anti-skipping | Every sucking head is installed with a vacuum detector that gives an alarm while a workpiece is skipped. | |

| Cellphone cover fixing | Fixture | |

| Number of sucking head | 2 | |

| Labeling capacity | 2 pcs/time | |

| Labeling materials | Cellphone accessories | |

| Labeling precision guarantee | Automatic position correct | |

| Pneumatic components | SMC | |

| Sensor | Keyence | |

| X-axis movement | AC Siemens servo motor | |

| Y-axis movement | AC Siemens servo motor | |

| Z-axis movement | AC Siemens servo motor | |

| Max. moving range of X-axis | 150mm |

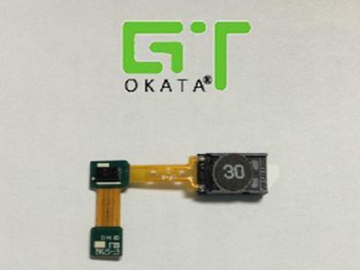

Applications of Mobile Phone Accessories Labeling Machine

The labeling machine is most often used for covers of electronic products, such as cellphones, tablets, cameras, GPS trackers and so on.

HDS Labeling Machine Features

1. The accessories labeling machinery is pretty flexible and its workstations can be exchanged, added and reduced.

2. Using Siemens control system, the labeling equipment runs stably and smoothly.

3. All pneumatic components are from SMC to ensure long lasting performance of our machine.

4. After sucking cellphone accessories, the label machine automatically adjusts the position to correct displacement during the sucking process.

5. The machine has a memory function. For next time use, X axis, Y axis and Z axis will automatically move to the labeling position. The operator doesn't need to adjust the labeling head, which saves a lot of time and labor cost.

6. A high degree of automation realizes a decrease in labor cost and product cost. In turn, the accessories for electronic products have a more attractive price than others.

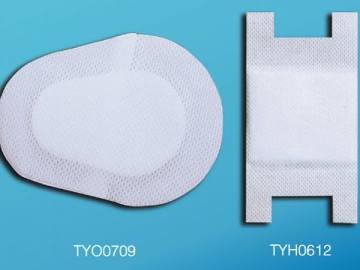

Samples