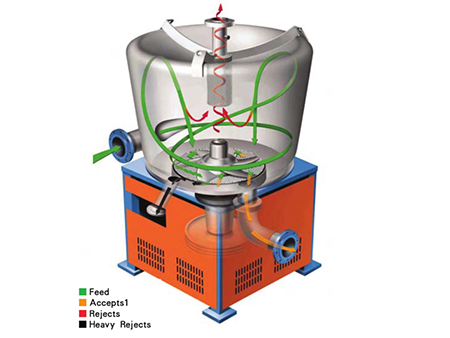

Float Purger

The float purger is a device used in the papermaking industry designed to efficiently remove impurities and waste materials from pulp. Using float purgers ensure the production of high-quality paper by maintaining the cleanliness and consistency of the pulp. It is widely adopted in various stages of papermaking, including waste paper recycling, pulp preparation, and paper production.

The float purger operates on the principle of flotation. Inside the device, pulp slurry is introduced through nozzles into the paper making equipment's tank. Air or other gases are injected, creating bubbles. These bubbles attach to impurities, causing them to rise to the surface and form a froth layer. This froth is then removed, while the clean pulp is discharged from the bottom, ready for further processing.

Features- Effectively separates and removes sand, fiber fragments, and other debris, enhancing the quality and smoothness of the paper

- Equipped with advanced control systems and sensors, the Float Purger allows for automated operation and monitoring, improving production efficiency and stability

- Features adjustable bubble generation and flow rate control to meet various pulp and process requirements

- Utilizes low-energy electric drive systems and energy-saving designs to reduce energy consumption and environmental impact

- Manufactured with corrosion-resistant materials, ensuring long-term use and stable performance

The float purger is versatile and can be applied in various stages of the papermaking process, including waste paper recycling, pulp preparation, and final production stages, ensuring impurities are effectively removed to produce high-quality paper. It is suitable for a wide range of paper products, from tissue to packaging paper.

Specifications| Type | |||

| Nominal Volume(m3) | 0.4 | 0.8 | 2 |

| Pressure Of Outflow Pulp (Kpa) | 0.2-0.25 | ||

| Treating Consistency (%) | 0.5-0.2 | ||

| Capacity Of Production(t/d) | 35-45 | 65-85 | 110-140 |

| Power Of Motor (kW) | 30 | 55 | 110 |

| Dimensions (L x W x H) (mm) | 1825 x 910 x1400 | 2600 x 1245 x 1955 | 3100 x 1700 x2570 |