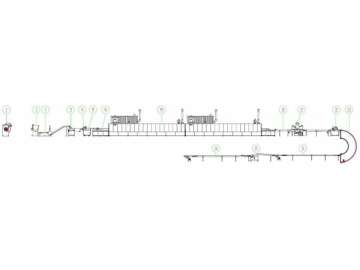

Bakery Equipment (For Soft Dough Biscuits)

Bakery Equipment

(For Soft Dough Biscuits)

,1

,13-5

Serving the food industry for more than 20years, Evergrowing has become a leading manufacturer of snack food machines and has been at thecutting edge of bakery equipment technology. We can create the mostcomprehensive range of food production lines for customers according to their demands,including hard biscuit production lines, waferproduction lines, soft biscuit productionlines, sandwich biscuit production lines, soda biscuit production lines,and cracker production lines.

Product Specifications

| Biscuit production line | Products | Working widths | Oven length | Capacity | Oven type |

| Equipped with rotary molder | Soft biscuit, cookies, etc. | 620, 800, 1000, 1200mm (further on request) | 20-80m | 200-2000 kg/h | Nature/Liquid gas; Electric |

Notes:

1. Energyconsumption: Natural gas 30-80m3/h (it is different as productchanges)

2. Power supply: 3-380V, AC, 50HZ

3. Production capacity: 200 -2000kg/h

4. Finished products qualified rate: ≥98%

5. Stainless steel type: 304

The soft biscuit production line is a set of outstanding bakery equipment for producingsoft biscuits. By means of high quality and performance as well as our excellentservices, this soft biscuit makingplant has been widely adopted by users in Europe, SouthAmerica, Africa and other regions.

The soft biscuit production line is a type of versatile biscuit machinery, suitable for the manufacturingof various soft biscuits, cookies, etc. Throughthe whole production process covering dough mixing, forming, baking, oilspraying, cooling, stacking and packing, it can produce golden, tasty and crispbiscuits.

Features of the Bakery Equipment

1. Biscuits produced by this bakery equipment boast uniform color,moderate moisture and excellent taste.

2. This biscuit making machine is designed and manufactured according to HACCPstandards. The main machine body is made of SUS304 stainless steel which givesit a beautiful appearance and is easy to clean. Employing a PLC controller withtouch screen, it enables more flexible operation.

3. Based on your specific conditions, you can choose from gas or electricovens.

4. The main motors of the bakery equipment feature variable frequency speedcontrol.

5. Both the dough forming machine and tunnel oven employ PLC control with touchscreens that have memory and feedback functions.

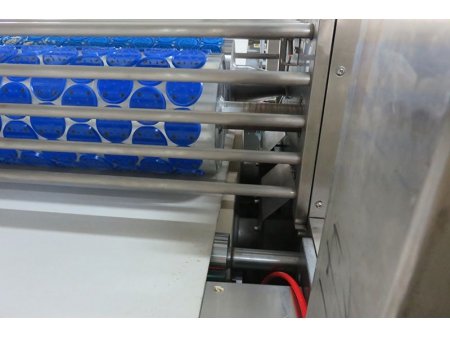

6. Conveyer belts in this biscuit production line are all made of food grade PUmaterials.

7. The conveyor belt driving roller and cutting roller are all covered withnon-toxic and oil resistant rubber.

8. According to your needs, we can offer you customized soft biscuit productionline and individual machines, as well as workshop design, worker training andcomplete technical formula.

Part Brands

1. Electrical Parts

Touch screen, frequency converter, PLC, electric controller: Panasonic,Schneider, Siemens

Fire pipe solenoid valve: France Burkert

Electric motor: U.S. Honeywell

Combustor: Italy Baltur

2. Mechanical Parts

Main driving motor reducer: SEW (Chinese brand)

Roll bearing: Japan NSK

· 12-3-1: Horizontal Dough Mixer

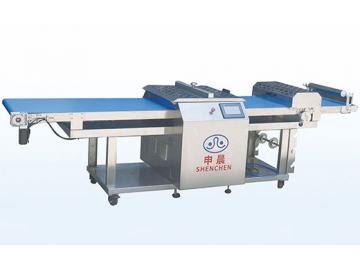

· 12-3-2: Dough Forming System

· 12-3-3: Tunnel Oven

· 12-3-4: Oil Spraying Machine &Powder Scattering Machine

· 12-3-5: 、、Cooling Conveyor, Stacker & PackingConveyor

Title: Bakery Equipment | Biscuit Production Line| Evergrowing

Keywords: Bakery equipment, biscuit production line, waferproduction line, biscuit making plant, biscuit machinery, snack food machinesmanufacturer

Description: This soft biscuit production line from Evergrowing isgreatly popular versatile bakery equipment specially designed for producing allkinds of soft biscuits, coolies, etc.

.jpg)