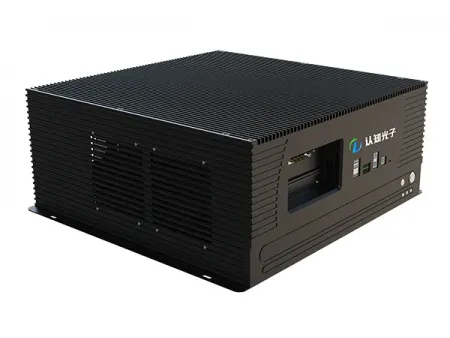

LWR-1000-J Laser Welding AI-Powered Control System

Request a Quote

Laser Welding System Components

Real-time control in laser welding using advanced AI algorithms

The LWR-1000-J laser welding AI-powered control system gives you complete control over your laser welding process. It is a high-efficiency, stable real-time inference control platform specifically developed for closed-loop laser welding. This laser welding control system delivers a reliable solution for weld quality monitoring and optimization by integrating image acquisition, spectral analysis, and real-time inference algorithms.

The laser welding control system meets the high-throughput, low-latency demands of laser welding and additive manufacturing processes with its powerful AI computing capabilities and low-latency data processing, driving the technology toward intelligent automation.

Parameters

| Performance | |

| Video inference time | < 1ms (single frame 1280x384 pixels, 12-bit) |

| Signal inference time | < 0.1ms(gigabit) |

| Built-in model | CNN,LSTM、DNN etc. |

| Processors | 3 × Nvidia Jetson AGX ORIN |

| CPU | 12-core Cortex A78 ARM 64-bit CPU, 2.2 GHz |

| GPU | 2048-core NVIDIA Ampere™ GPU, 64 Tensor Cores2, 1.3 GHz |

| DL accelerator | 2× NVDLAv2,1.6GHz |

| RAM | 64GB LPDDR5,204.8GB/s |

| Flash | 64GB eMMC |

| Input Interface | |

| PCIE | 1 × PCIE4.0 ×16 /×8 |

| Camera interface | 4 × Micro BNC/CXP-3/CXP-6/CXP-12 support3/6/12 Gbps |

| Output Interface | |

| EtherCAT | 2 ×1.0GB wired network port, support EtherCAT as the master, can access slave devices |

| Other Interfaces | |

| USB | 2 × USB3.2 1 × Micro USB |

| HDMI, GPIO, CAN |

| Storage | |

| M.2 | 3 × M.2 KEY M for expanded storage |

| Power | |

| Type | AC |

| Input voltage | 220V |

| Working Environments | |

| Operating temperature | -25℃to 60℃ |

| Storage temperature | -30℃to 85℃ |

| Vibration | 3Grms@5-500 Hz, 0.5 hr/axis |

| Attack | 10G / 11 ms |

| Physical Properties | |

| Dimension (Wx D x H) mm | 500×500×220 |

| Weight | 11Kg |

| Installation | Desktop/Wall-mounted |

Features

- Instantaneous control

The laser welding control system offers sub-millisecond latency from feedback to control, enabling precise management of the highly dynamic melt pool and keyhole behaviors in both laser welding and additive manufacturing processes. - Superior AI computing

With an AI computing capacity of 825 TOPS, the AI-powered welding control system is built to handle massive datasets, allowing for rapid and sophisticated model inference. - Integrated data fusion

By acquiring multi-modal data via high-speed image and spectral capture cards, the system leverages AI algorithms to perform real-time quality assessments and dynamically adjust laser parameters for precise process control. - Unmatched bandwidth

Featuring CXP12 and PCIe 4.0 interfaces, the laser welding control system achieves an impressive 178 Gbps transmission bandwidth, guaranteeing both efficient data transfer and real-time responsiveness.

Applications

- Laser welding

Quality monitoring & closed-loop control. - Laser cutting

Quality monitoring & closed-loop control. - Additive manufacturing

Quality monitoring & closed-loop control.