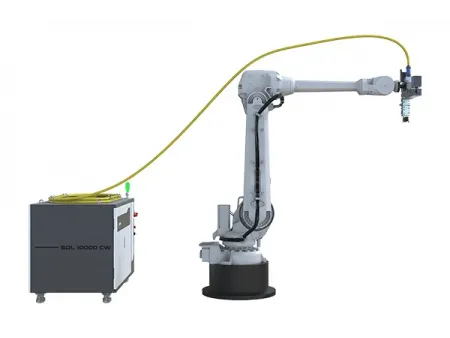

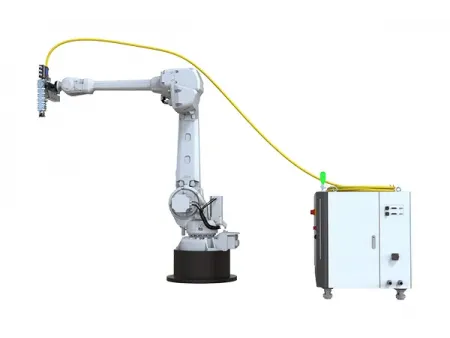

CPL-10000- RW/GW Medium-Thickness Steel Autogenous Laser Welding System

Laser Welding System

Robotic welding system for the autogenous welding of thin to medium-thickness steel of up to 20mm

CPL-10000-RW/GW medium-thickness steel autogenous laser welding system is built around a 10kW-class full-vector optical field-controlled fiber laser. It integrates a "5-in-1" in-weld monitoring sensor and a real-time laser welding control platform. With modular and configurable laser welding software, the system is capable of handling complex working conditions, solving key challenges in medium-thickness plate laser welding—such as alignment tolerance and welding defects. It enhances welding quality, effectively mitigates common defects like pores, cracks, and undercutting, and improves weld strength and fatigue life.

| Welding Material | High-strength steel, stainless steel, carbon steel |

| Welding Thickness | 5-20mm |

| Welding Speed | 0.5-2.0m/min |

| Welding Method | Single-pass single-layer laser deep fusion welding, single-sided weld with double-sided formation, no filler wire or material required |

| Welding Characteristics | Adaptive to weld seam tolerance, free of welding cracks, pores, and lack of fusion |

| Welding Laser | 10kW Software Defined Fiber Laser (SDL-10000-CW) |

| In-Process Monitoring Sensor | "5-in-1" Laser Welding Process Monitoring Sensor (WMS-100-FIO) |

| Closed-Loop Controller | Laser Welding AI-Powered Control System (LWR-1000-J) |

| Laser Welding Head (including a vision tracking and analysis module) | 10kW Modular Laser Welding Head (LWH-10000-F1.0/2.0/3.0) Active illumination, 1kHz imaging frame rate, 1280×384 pixel single-frame image, 12-bit |

- Superior weld quality

Experience exceptional weld quality and a smooth, uniform finish. By leveraging the high-speed dynamic beam of our full-vector optical field-controlled laser, the autogenous laser welding system actively prevents common defects such as pores and cracks, significantly reducing the need for post-processing. - Increased efficiency

The laser welding system's automatic adaptation to weld assembly tolerances allows you to complete single-sided, single-pass welding on metals from 5mm to 20mm thick. For example, you can achieve impressive welding speeds of up to 2m/min on 10mm-thick steel. - Extended fatigue life

Boost the longevity and durability of your welds. The welding process offers a thermal efficiency that is twice that of conventional lasers, resulting in minimal damage to the base material and a significant extension of the weld's fatigue life—ensuring a greater return on your investment. - Cost savings

Dramatically lower your operational costs. Our autogenous welding process eliminates the need for filler wire while still meeting required mechanical performance standards. This high-quality, consumable-free approach minimizes material waste, reduces rework, and significantly lowers your overall production costs. - Intelligent process monitoring

The steel laser welding system provides comprehensive real-time oversight of the entire welding process. Equipped with multiple sensors, it continuously monitors critical parameters like power and speed. Its self-learning capabilities allow it to automatically adjust parameters to optimize quality and reduce the time spent on process debugging. Every weld is recorded in real-time for quick, post-weld quality checks.

Thanks to its high efficiency and precision, this autogenous laser welding system is ideal for:

- Shipbuilding segmented plate assembly

- Oil and gas pipelines

- Wind turbine towers

- Pressure vessels

- Steel mill prefabricated plates

- Construction machinery welding

Innovative laser technology and precise control ensure excellent performance in quality, efficiency, cost, and process monitoring. Its highly integrated and modular design suits diverse materials and industries, making it the optimal solution for medium and thick steel welding.