Single Point Straight Side Press

DH1 Stamping Presses

- Capacity 110T to 315T

- Strokes per minute 20SPM to 90SPM

- Stroke length 80mm to 250mm

- Slide area 650×470mm to 1000×700mm

The DH1 single point straight side press is a high-precision mechanical press built with a D-frame structure. This press combines precision, production efficiency, and structural stability, making it well-suited for automotive, electronics, appliance, aerospace, and hardware manufacturing industries.

With a capacity from 110T to 315T and stroke speeds between 20 and 90 SPM, the single point straight side press supports demanding production environments. Built to Japan’s JIS grade-1 precision standards, it ensures consistent, accurate performance over long-term operations.

- Tools: wrench grooves, pliers, screwdriver heads, hammer heads

- Kitchenware: pot lids, knives, baking trays

- Home appliances: washing machine shells, refrigerator door panels, microwave oven panels, air conditioner casings

- Hardware: hinges, locks, screws

- Electronics: smartphone frames, metal casings, circuit board brackets, LCD parts

- Automotive components and more

- High-rigidity D-frame structure for minimal deformation and excellent stability

- High-torque dry/wet clutch and brake system for smooth, reliable operation

- Precision six-surface guideways for stable, accurate stamping

- Hydraulic overload protection for safe and efficient use

- Quick die change system to increase productivity

- Single crankshaft transmission for balanced force and smooth motion

- Intelligent safety and control management system

| Model | Unit | ||||||||||

| Type | V | H | V | H | V | H | V | H | V | H | |

| Capacity | T | 110 | 160 | 200 | 260 | 315 | |||||

| Rated tonnage point | mm | 6 | 3 | 6 | 3 | 6 | 3 | 7 | 3.5 | 7 | 3.5 |

| Strokes per minute | S.P.M | 30-60 | 60-90 | 20-50 | 40-70 | 20-50 | 35-70 | 20-40 | 40-50 | 20-35 | 30-50 |

| Stroke length | mm | 180 | 80 | 200 | 90 | 200 | 100 | 250 | 150 | 250 | 150 |

| Max. shut height | mm | 360 | 410 | 460 | 510 | 460 | 510 | 500 | 550 | 550 | 600 |

| Die height adjustment | mm | 80 | 100 | 110 | 120 | 120 | |||||

| Slide area | mm | 650×470×80 | 700×550×90 | 850×630×90 | 950×700×100 | 1000×750×110 | |||||

| Slide plate thickness | |||||||||||

| Bolster area | mm | 1090×600×110 | 1190×800×140 | 1400×820×160 | 1500×840×180 | 1600×900×200 | |||||

| Bolster plate thickness | |||||||||||

| Air pressure required | kg/cm² | 6 | 6 | 6 | 6 | 6 | |||||

| Main motor | kW.p | 11×4 | 15×4 | 15×4 | 18.5×4 | 30×4 | |||||

| Slide adjustment mechanism | Electric | ||||||||||

| Precision | mm | JIS 6402 (Japan) Grade-1 | |||||||||

| Die cushion | 1 pad, 1 cylinder | ||||||||||

| Die cushion capacity | ton | 6.3 | 10 | 14 | 14 | 14 | |||||

| Die cushion stroke length | mm | 70 | 80 | 100 | 100 | 100 | |||||

| Die cushion pad area | mm | 500×350 | 650×420 | 710×480 | 810×480 | 810×480 | |||||

Standard Configurations

- Variable speed drive

- Hydraulic overload protector

- Electrical slide adjustment

- Electric die height indicator

- Slide and die counterbalance system

- Misfeed detector

- Power socket

- Rotary cam switch

- Crank angle indicator

- Electrical stroke counter

- Air source connector

- Overrun safety device

- Maintenance tool box

- Operating manual

Optional Configurations

- Photoelectric safety device

- Automatic grease lubrication system

- Pneumatic die cushion

- Preset counter

- Foot switch

- Quick die change (die lifter, die clamp, die arm)

- Slide knockout

- Anti-vibration mounts

- Feeder (pneumatic, mechanical and NC)

- Uncoiler

- Leveler

- Manipulator

- Die area light

- Touch screen (preset and total counter)

- PACLDO control system

- Human-machine control system

- Wet clutch

Designs are subject to change without prior notice and can be customized according to your requirements.

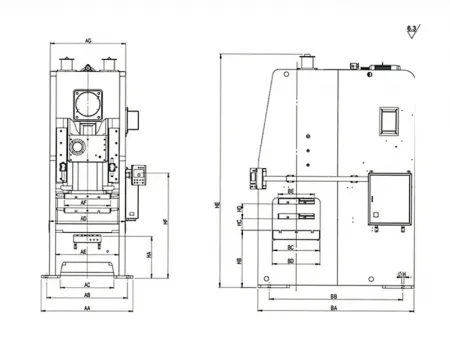

Outline Dimensions (mm)

| Model | DH1-80 | DH1-110 | DH1-160 | DH1-200 | DH1-260 | DH1-315 | ||||||

| Type | V | H | V | H | V | H | V | H | V | H | V | H |

| AA | 1210 | 1320 | 1520 | 1710 | 1730 | 1800 | ||||||

| AB | 1040 | 1180 | 1340 | 1430 | 1480 | 1640 | ||||||

| AC | 690 | 720 | 870 | 990 | 990 | 1062 | ||||||

| AD | 930 | 1090 | 1190 | 1400 | 1500 | 1600 | ||||||

| AE | 780 | 920 | 1000 | 1160 | 1160 | 1260 | ||||||

| AF | 560 | 650 | 700 | 850 | 950 | 1000 | ||||||

| AG | 880 | 1060 | 1160 | 1340 | 1360 | 1360 | ||||||

| BA | 1770 | 1850 | 2350 | 2600 | 2585 | 2775 | ||||||

| BB | 1540 | 1640 | 2000 | 2180 | 2215 | 2305 | ||||||

| BC | 550 | 600 | 880 | 820 | 820 | 900 | ||||||

| BD | 560 | 610 | 890 | 830 | 830 | 910 | ||||||

| BE | 420 | 470 | 550 | 630 | 700 | 750 | ||||||

| HA | 750 | 760 | 797 | 880 | 930 | 805 | ||||||

| HB | 830 | 850 | 920 | 1040 | 1080 | 1000 | ||||||

| HC | 340 | 380 | 360 | 410 | 460 | 510 | 460 | 510 | 500 | 550 | 550 | 600 |

| HD | 150 | 70 | 180 | 80 | 200 | 90 | 200 | 100 | 250 | 150 | 250 | 150 |

| HE | 2952 | 3205 | 3655 | 4065 | 4107 | 4316 | ||||||

| HF | 1750 | 1747 | 1895 | 1910 | 1795 | 1763 | ||||||

| ØH | Ø28 | Ø35 | Ø35 | Ø44 | Ø44 | Ø44 | ||||||

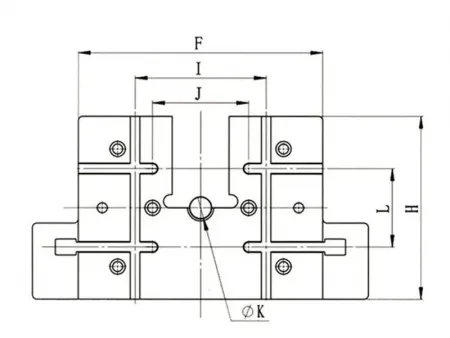

Bolster & Slide Plate Dimensions

| Model | A | B | C | D | E | F | H | I | J | K | L |

| DH1-80 | 360 | 180 | 150 | 930 | 550 | 560 | 420 | 300 | 220 | Ø50 | 180 |

| DH1-110 | 400 | 200 | 160 | 1090 | 600 | 650 | 470 | 300 | 220 | Ø50 | 220 |

| DH1-160 | 440 | 220 | 220 | 1190 | 880 | 700 | 550 | 300 | 175 | Ø65 | 220 |

| DH1-200 | 480 | 240 | 280 | 1400 | 820 | 850 | 630 | 420 | 200 | Ø65 | 300 |

| DH1-260 | 520 | 260 | 290 | 1500 | 820 | 950 | 700 | 420 | 200 | Ø65 | 300 |

| DH1-315 | 520 | 260 | 290 | 1600 | 900 | 1000 | 750 | 420 | 200 | Ø65 | 300 |

Our product brochure

The single point straight side press brings stability, accuracy, and reliability to your production line. Contact us to learn how this press can meet your stamping needs and support your manufacturing process.