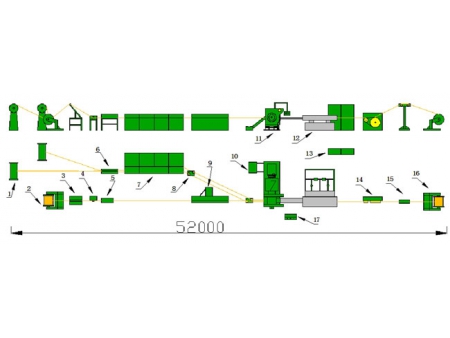

3000A 8-10 Inches Aluminium Extrusion Process

Request a Quote

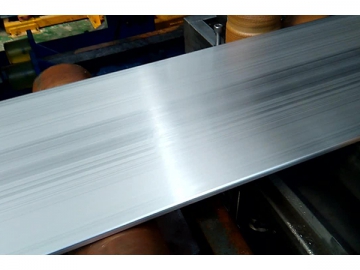

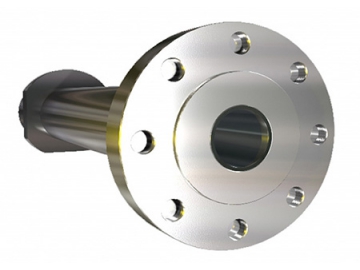

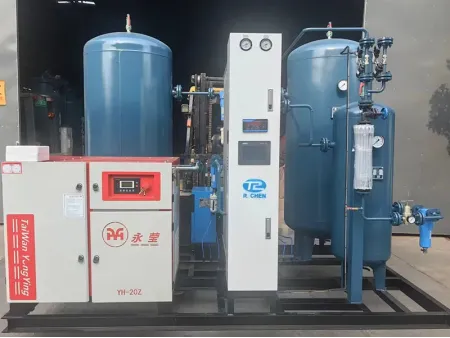

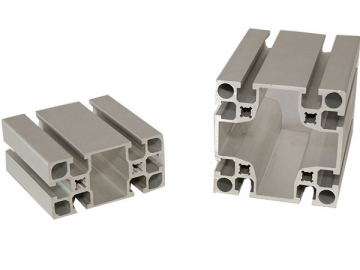

(8''-10'') 3000A: This quenching system is special designed for billet diameter range of 8-10 inches and corresponding extruder tonnage, which is used with profiles with large wall thickness. Based on B model, this design increases the lengths of air cooling at the backside, to ensure optimal cooling effect and minimize deformation under high speed extrusion. It is widely working with large extruder.

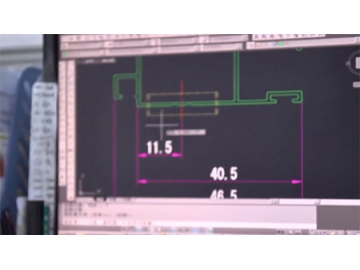

Main Tech. Data| 1 | Billet spec.: diameter φ203mm---φ254mm | 8 "---10" |

| 2 | Profile envelope : width is 380mm, height 300mm | 380mm, 300mm |

| 3 | Required space for the production line | 13500mm |

| 4 | Min. space from the center line of press to workshop wall | 2800mm |

| 5 | Max. working power | 145kw |

| 6 | Total power of air cooling | 136kw |

| 7 | Front air cooling nozzles | 6 columns |

| 8 | Rear air cooling nozzles | 2 columns |

| 9 | Water cooling nozzles | 6 columns |

| 10 | Mist cooling nozzles | 6 columns |

| 11 | Min. flow of industrial softened water per quenching system | 100m³ |

| 12 | Water hardness | 3 ~ 5 °F |

| 13 | Inlet water temp. at quenching system | < 35 °C |

| 14 | Compressed air pressure at top | 6 Bar |

| 15 | Max. flow rate | 3m3/min |

Related products

Send Message

Other Products

Most Recent

More

Other Products

Videos