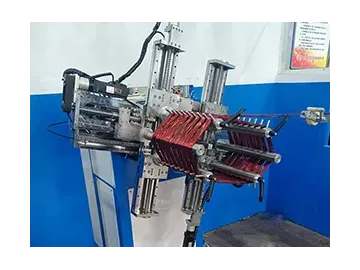

Motor Coil Winding Machine

Request a Quote

Coil Manufacturing Equipment & Technology

Automatic coil winder with wire tension control for electric motor coils

Motor coil winding machine is widely used for the production of large and medium-sized motor stator coils. It is equipped with an automatic interlocking, with a floating device for automatic compaction and straightening of the copper wire, which also maintains a controlled and constant conductor tension. In addition, the electrical components used in this coil winding machine are provided by renowned suppliers to ensure the long-term stable operation of the equipment.

Features

- Motor coil winding machine adopts Japan Mitsubishi PLC system and can be controlled through the control cabinet and touch screen, which has anti-mistake touch protection. All parameters can be input, adjusted and saved via the touch screen.

- The wire is unwound by a constant tension. After the previous coil has been wound and the copper wire has been cut, the coil winding machine is able to maintain the tension on the copper wire within the set tension value.

- Motor coil winding machine carries out automatic winding process, covering automatic wire loading, wire counting, wire cutting, etc. The winding length can be automatically adjusted to the set length.

- The feeding process is controlled by servo motor, which can ensure the accurate feeding length.

- It has a detection device for the inspection of wire lack or broken wire, which enables the electromagnetic wire passes through the device, if the wire is broken or the number of the wire is insufficient, the proximity switch is sensed to activate the alarm and shut down the machine. And then, the coil winder will be restarted and continue to work after the problem being solved.

- Motor coil winding machine is able to automatically wind between slots. After a slot is wound, it will jump to the next slot for winding.

Working Process

- Adjust the spindle speed to adapt to motor coil production process.

- Adjust the precision of the tensioning.

- Put the coil in the designated location and press the button to close the cover.

- After the coil finishes winding the set number of turns, it will be locked automatically.

Specifications

| Traction line length | 100-600mm |

| Conductor width | 0.2-3.5mm |

| Conductor thickness | 1-36 |

| Coil length | 300-950mm |

| Coil width | 200-600mm |

| Winding bobbin | R20, R25 |

| Slot number | 4-10 |

| Winding speed | 5-100r/min |

| Counting capacity | 999 |

| Maximum load | 1400kg |