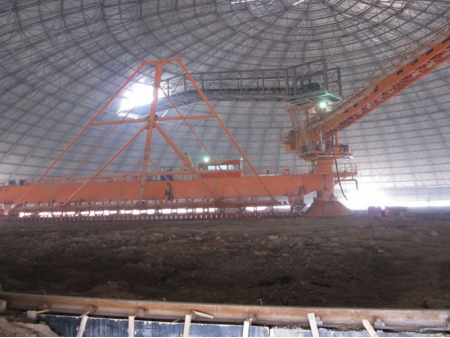

Circular Stacker Reclaimer

The circular stacker reclaimer is usually used for pre-homogenization raw materials in the stockyard. The circular stacker reclaimer system covers a small area and can continuously stack and reclaim materials. It is an ideal homogenizing equipment for bulk materials like cement and coal.

| Model | Stacking capacity | Inlet belt width | Reclaiming capacity | Rail type |

| 1800t/h | 1400mm | 1100t/h | 120kg/m | |

| 1200t/h | 1000mm | 500t/h | 80 kg/m | |

| 500t/h | 800mm | 200t/h | 50 kg/m |

Boom conveyor belt

The boom conveyor belt is supported by a roller attached to the frame, driven by a gear motor (SEW), and is equipped with a backstop device.

Travelling mechanism

The travelling mechanism consists of walking beams and is driven by geared motor (SEW) driving equipment.

Hydraulic lifting device

The hydraulic lifting device is composed of a hydraulic station and a hydro-cylinder. The boom conveyor achieves a luffing motion through the movement of the hydro-cylinder.

Operation room

The operation room is mounted on the steel structural support, and is equipped with an interior PLC system and electrical cabinet.

Rake system

- Structural design

The overall design of this circular stacker reclaimer can meet different customer working conditions. The range can be adjusted according to the yard size in order to ensure the stacking and reclaiming capacity and storage requirements are met. - Reliable Performance

SINOMALY takes into full consideration all mechanical characteristics of the stacker and reclaimer system. A computer is used to design the circular stacker reclaimer’s structure, which ensures the full structural and component performance.

All steel raw materials are pretreated. The scraper uses a high strength alloy in order to enhance the corrosion resistant and abrasion resistance of the contact surface, which improves the scraper service life.

Large components are machined by large-scale milling machines, thus ensuring the structural components precision and improving the machining quality. All structures are assembled in the factory and then transported to the customer yard for installation and commissioning. For long-distance customers, we will transfer all standard parts and consumable parts to the yard, as well as send engineers to the site to provide assembly and debugging services. Soft start and frequency conversion control are used in the control system, which can reduce the damage to the circular stacker reclaimer caused by material impact, as well as save energy. - Automatic operation

The bulk material handling equipment can be operated unmanned and can stack and reclaim materials in a fully automatic mode. Manual operation is also easy, and operators just need a fast, easy training session. Several operation modes for material stacking and reclaiming are set up to fully meet the requirements of different stockyard working conditions.