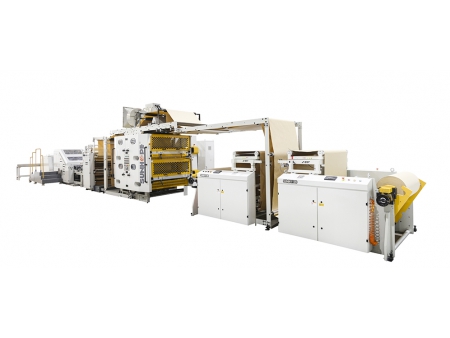

SBH330B DL02 Roll Fed Square Bottom Paper Bag Machine (Two Ply Unit)

Request a Quote

Our SBH150B/330/450B series roll feed square bottom bag machine adds an inline DL01/02/03 servo driven two ply unit in order to produce paper bags with an internal full film lamination or two ply paper bags. It is widely used for the production of flour bags, and features an increased market potential for the customer, as well as an improved sales value of the finished product.

- Two Ply Unit

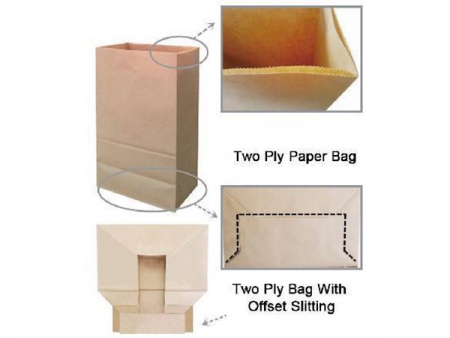

Bag Schematic Diagram

Specifications

-

Model:

SBH150 DL01 - Paper Thickness (gsm):

- 40-150

- Tube Cut Off Length (mm):

- 191-385

- Bag Face Width (mm):

- 80-200

- Bag Bottom Size (mm):

- 50-100

- Max. Speed (bags/min):

- 250

-

Model:

SBH150B DL01 - Paper Thickness (gsm):

- 40-150

- Tube Cut Off Length (mm):

- 191-430

- Bag Face Width (mm):

- 80-200

- Bag Bottom Size (mm):

- 45-100

- Max. Speed (bags/min):

- 250

-

Model:

SBH330 DL02 - Paper Thickness (gsm):

- 45-180

- Tube Cut Off Length (mm):

- 280-540

- Bag Face Width (mm):

- 120-330

- Bag Bottom Size (mm):

- 70-150

- Max. Speed (bags/min):

- 230

-

Model:

SBH330B DL02 - Paper Thickness (gsm):

- 50-180

- Tube Cut Off Length (mm):

- 280-540

- Bag Face Width (mm):

- 150-330

- Bag Bottom Size (mm):

- 70-180

- Max. Speed (bags/min):

- 220

-

Model:

SBH450B DL03 - Paper Thickness (gsm):

- 70-180

- Tube Cut Off Length (mm):

- 368-762

- Bag Face Width (mm):

- 200-450

- Bag Bottom Size (mm):

- 90-205

- Max. Speed (bags/min):

- 220

-

Model:

SBH450C DL03 - Paper Thickness (gsm):

- 70-180

- Tube Cut Off Length (mm):

- 368-762

- Bag Face Width (mm):

- 200-450

- Bag Bottom Size (mm):

- 120-260

- Max. Speed (bags/min):

- 220

| Technical Info | | | | | | |

| Paper Roll Width (mm) | 280-640 | 280-640 | 405-1050 | 465-1050 | 610-1310 | 690-1310 |

| Paper Roll Dia. (mm) | ≤1500 | ≤1500 | ≤1500 | ≤1500 | ≤1500 | ≤1500 |

| Paper Roll Core Dia. (mm) | Φ76 | Φ76 | Φ76 | Φ76 | Φ76 | Φ76 |

| Paper Thickness (gsm) | 40-150 | 40-150 | 45-180 | 50-180 | 70-180 | 70-180 |

| Tube Cut Off Length (mm) | 191-385 | 191-430 | 280-540 | 280-540 | 368-762 | 368-762 |

| Bag Face Width (mm) | 80-200 | 80-200 | 120-330 | 150-330 | 200-450 | 200-450 |

| Bag Bottom Size (mm) | 50-100 | 45-100 | 70-150 | 70-180 | 90-205 | 120-260 |

| Max. Speed (bags/min) | 250 | 250 | 230 | 220 | 160 | 160 |

| Total Power (kW) | 15.75 | 15.25 | 21.5 | 21.5 | 25.8 | 25.8 |

| Machine Weight (kg) | about 8600 | about 8600 | about 11500 | about 12000 | about 14000 | about 14000 |

| Machine Size ((L×W×H)(m) | 14.6×2.6×1.96 | 14.6×2.6×1.96 | 17.5×3.1×1.96 | 17.5×3.1×1.96 | 19×3.9×2 | 19×3.9×2 |

| Three Types of Bottom Seal | yes | yes | yes | yes | yes (Two) | yes (Two) |

| Servo Lip Cut Device | yes | yes | yes | yes | no | no |

Features

- The roll fed square bottom paper bag machine is equipped with a Japanese Mitsubishi servo system and SICK photocell for correction, so that users can accurate track printed material, and minimize adjustment and pre-set times.

- It is equipped with a Mitsubishi electric control system and Mitsubishi motion controller (CPU). This achieves an integration of an optical fiber in order to achieve a high speed and high precision, motion control and production flow test. With a touch screen display, the operation functions are clear, and feature a great human to machine interface.

- Two sets of reel stand sections are equipped with an Italian RE tension system and German BST WEB guiding system in order to reduce waste and improve efficiency.

- The two ply paper bag machine can produce bags with offset bottom slitting.

- Two ply bags can have partial or full gluing between plies.