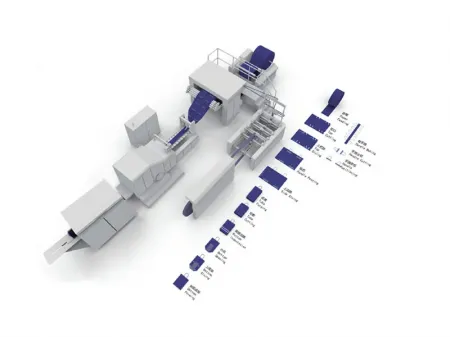

Fully Automatic Roll-fed Square Bottom Paper Bag Machine

Paper bag making machine for square bottom bags with or without handle

The roll-fed square bottom paper bag production line handles the entire manufacturing process, including feeding paper rolls, producing and attaching handles, forming the bag tubes, cutting the tubes to the desired size, and shaping the square bottoms. This fully automated workflow significantly reduces labor costs and enhances production efficiency, making it an ideal solution for businesses with high output demands. Equipped with a photoelectric detection system, the paper bag making equipment ensures precise cutting lengths, maintaining consistency and quality across batches. The Siemens PLC control system delivers stable and efficient performance while minimizing the time required to adjust for different bag sizes. Additionally, the integrated collection platform and counting function streamline the packing process for completed bags, boosting overall workflow efficiency.

This paper bag making machine is capable of producing high-quality paper bags in various styles, tailored to meet the demands of industries such as food and apparel. Its reliable performance and flexibility make it a valuable asset for businesses aiming to manufacture durable and attractive paper handbags at scale.

- 1. Roll Feeding

- 2. Side Gluing

- 3. Tube Forming

- 4. Paper Cutting

- 5. Bottom Creasing

- 6. Bottom Opening

- 7. Bottom Gluing

- 8. Bottom Sealing

| Paper Handle Size Range | |

| A: Handle Length | 110-120 mm |

| B: Patch Width | 45-50 mm |

| C: Patch Length | 152.4 mm |

| D: Handle Width | 76.2 mm |

To cater to varying customer needs, we provide a selection of bottom styles for paper bags without handles (produced by semi-automatic paper bag making machines). These bag bottom styles require specialized forming molds, which differ from those used in fully automatic bag-making machines, ensuring compatibility and flexibility in semi-automatic production.

Y= Bottom Folding= Bottom Size × (65%-75%)

X= Gluing Zone =25mm-30mm

| Model | ZH-QFJ13 | |

| Mode | With Handle | Without Handle |

| Paper Roll Width | 590-990mm | 400-990mm |

| Max. Paper Roll Diameter | Ø1200mm | Ø1200mm |

| Material Core Diameter | Ø76mm (3”) | Ø76mm (3”) |

| Paper Thickness | 80-160g/m² | 55-160g/m² |

| Bag Width | 200-330mm | 125-330mm |

| Paper Tube Length | 270-410mm | 270-530mm |

| Bag Bottom Size | 60-150mm | 60-150mm |

| Handle Rope Height | 110-120mm | / |

| Handle Rope Diameter | Ø4-6mm | / |

| Handle Patch Length | 152.4mm | / |

| Handle Patch Width | 45-50mm | / |

| Paper Patch Roll Diameter | Ø1200mm | / |

| Paper Patch Roll Width | 90-100mm | / |

| Paper Patch Thickness | 100-250g/m² | / |

| Max. Production Speed | 120bags/min | 220bags/min |

| Total Power | 42kw | |

| Total Weight | Approx. 16000kg | |

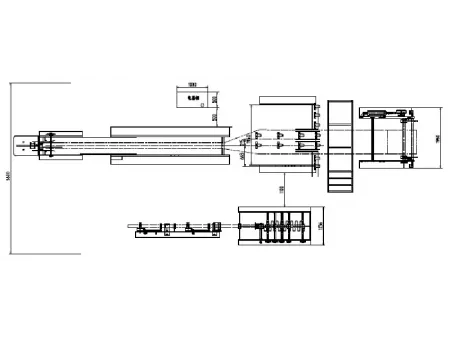

| Overall Dimensions (L×W×H) | 13000×6000×H3100mm | |

| Power | 3 phases, 380V±10%, 50 Hz |

| Compressed Air | Pressure: 0.6 MPa Volume: approx. 1 m³/hour Oil and humidity: ≤8 mg/m3 |

| Installation Height | Max. altitude: 1500 m |

| Ambient Requirement | Relative moisture: max. 65% when 40℃ Temperature range: 10-40℃ |