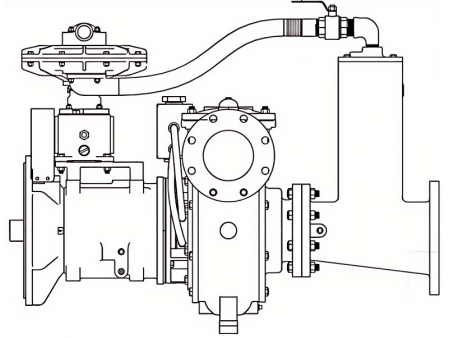

Dry-priming Dewatering Pump, MP Series

The MP series slurry dewatering pump is a vacuum-assisted, dry-priming pump designed for efficient handling of both solids and liquids across a wide range of industries. Engineered to tackle the most challenging solids-handling applications, it features a heavy-duty base with an integrated skid and a compact design that incorporates a vacuum-assisted dry-priming system.

This versatile slurry pump is ideal for applications such as mining, quarrying, industrial operations, water discharge, muddy water transfer, general water transportation, and environmental water management.

| Model | Inlet Dia. | Outlet Dia. | Impeller Dia. | Max. Solids Handling Size | Max. Flow Rate | Max. Head | Speed Range | Shaft Power Range (based on Specific Gravity = 1.0) |

| (inch) | (inch) | (inch) | (inch) | (m3/h) | (m) | (r/min) | (hp) | |

| 4 | 3 | 19.5 | 0.75 | 182.7 | 250 | 1400-2400 | 50-250 | |

| 4 | 4 | 8.25 | 3.25 | 304.18 | 36.6 | 800-2200 | 2-30 | |

| 4 | 4 | 14 | 3 | 370 | 130 | 1200-2300 | 20-165 | |

| 6 | 4 | 22 | 2 | 367.74 | 204 | 1200-1900 | 100-350 | |

| 6 | 6 | 10 | 3 | 601.55 | 50 | 1400-2200 | 15-75 | |

| 6 | 6 | 11 | 3 | 635 | 49 | 1200-2000 | 15-75 | |

| 6 | 6 | 12 | 3 | 703.7 | 73 | 800-2200 | 10-150 | |

| 6 | 6 | 14 | 3 | 669 | 88.45 | 1400-2000 | 50-125 | |

| 8 | 6 | 13.5 | 1.67 | 624.25 | 85.4 | 800-2100 | 15-175 | |

| 8 | 6 | 17.2 | 1.14 | 720 | 112 | 800-1900 | 10-250 | |

| 8 | 6 | 22 | 2 | 942 | 200 | 1200-1900 | 150-800 | |

| 8 | 8 | 12.25 | 3 | 1021.5 | 61 | 600-2000 | 5-100 | |

| 10 | 8 | 17.5 | 3.5 | 1577 | 135 | 1400-2000 | 100-400 | |

| 10 | 8 | 22 | 4 | 1929.5 | 180 | 800-1800 | 100-1000 | |

| 10 | 10 | 12 | 4 | 1225.8 | 35 | 1000-1800 | 20-100 | |

| 12 | 10 | 22 | 3 | 2360 | 240 | 1200-2100 | 400-1750 | |

| 12 | 12 | 17.25 | 3.75 | 2060 | 91.5 | 580-1780 | 15-300 |

- User-Friendly Vacuum Priming System

The DEFU pump’s self-priming system offers outstanding features such as high air-handling capacity, strong vacuum performance, low operating temperature, and a maintenance-free design. It operates without the need for oil or mechanical seals, ensuring reliable and efficient performance. - P-S-P(Prime-Sleep-Prime) Auto Switch System

The EVP (Electric Vacuum Priming) system automatically enters sleep mode once priming is complete. For general-purpose applications, the EVP system operates for only a few seconds during the priming process. This minimal usage significantly reduces the need for daily maintenance and makes spare part replacement virtually unnecessary throughout its service life. - Dry Running Protection System

Available configurations include an oil reservoir–lubricated mechanical seal, an air cushion–protected mechanical seal, and grease-lubricated lip seals. Each of these options is designed to ensure reliable dry running performance over extended periods. - Easy Maintenance Structure

The vacuum pump cover can be conveniently removed from the non-drive end, allowing the slides to be easily pulled out for inspection or replacement. Maintenance of the centrifugal pump is also simplified — the impeller, wear ring, and mechanical seal are easily accessible without the need to remove the diesel engine or pump frame, thanks to the fully openable suction cover design. - Mechanical Seal System

The DEFU mechanical seal system utilizes Type I and Type II mechanical seals, eliminating the need for flush water or packing. This not only reduces operating costs and service time but also avoids messy leaks. The result is a longer-lasting seal, minimizing downtime and lowering maintenance costs throughout the pump’s service life.

- Slurry transportation

- Mine dewatering system

- Washing and scrubbing

- Sand reclamation

- Tunnelling

- Quarrying

- Transfer of decantation liquids

- Flood control project

- Wellpoint dewatering

- Industrial and building drainage

- Municipal sewage engineering

- Storm water and sea water transportation

- Marine washing

- Domestic sewage

- Wastewater treatment plant

- Rain water dewatering

What are the options for the pump materials?

- CD4MCu material is primarily used for handling highly corrosive liquids, including strong acids, strong alkalis, seawater, and other aggressive media under high temperature and high pressure conditions.

- A05 (High-Chromium Iron) material offers high hardness and excellent wear resistance. It is suitable for handling high specific gravity fluids and applications involving solid particles where durability and abrasion resistance are critical.

Which types of mines are suitable for our mining drainage pumps?

Built to withstand harsh mining conditions, our diesel-powered drainage pumps provide reliable dewatering solutions for open-pit coal, copper, gold, iron ore, bauxite, phosphate, and nickel mines—particularly in off-grid or remote locations.

Who are the global leaders in slurry dewatering pump?

For your reference, the top global slurry dewatering pump brands include Cornell Pump, Gorman-Rupp, Godwin, KSB, Sykes, Thompson, Pioneer, Varisco, Selwood, Multiflow, and others.

Related Names

Dewatering Pump | Flood Pump | Irrigation Pump | Drainage Pump | Multiflow Pump | Dewatering and Sewage Pump | Wellpoint Dewatering Pump | Sludge and Bentonite Pumps