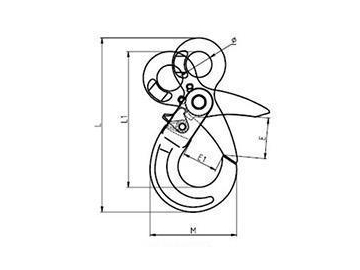

Key Eye Point S with Self Locking Plate

Request a Quote

BLT103 Rigging Hardware

- Working Load Limit 0.3-18t

- Rotation 360 degree

Designed to excel in confined spaces and demanding lifting scenarios, this key eye point with self-locking plate offers a working load limit ranging from 0.3t to 18t. The lifting eye rotates through 360° adjustable in the direction of the load and combines advanced strength, compact design, and self-locking features to enhance efficiency and safety. It is ideal for precision lifting in wind power installations, industrial applications, and marine operations.

Inspection and Standards

- Passed 6g plug gauge inspection for precision-threaded holes

- Withstood 1.5x load fatigue testing for 20,000 cycles and 2.5x rated load testing

- Magnetic particle inspection ensures crack-free integrity

- Manufactured to EN1677-1 standards with certified test reports available upon request

Applications

- Wind power: Prevents equipment damage from fixed lifting angles, ensures safe blade positioning during lifting and installation

- Port operations: Suitable for industrial components and container lifting, with resistance for high-chloride corrosive environments

- Applicable in various other industries such as oil and gas drilling, equipment transportation, and industrial plants

Key Features

- Enhanced material composition for improved durability and resilience

- Optimized tensile strength and fatigue performance, outperforming BLT94 key eye point under 90° load conditions

- Precision one-piece forging with advanced heat treatment for increased hardenability

- Eco-friendly coating with over 400 hours of salt spray resistance, suitable for marine and corrosive environments

- Innovative patented symmetrical design for improved aesthetics and balance, offering full 360° rotation

- Equipped with a self-locking plate for quick and tool-free installation

- Compact build designed for tight and challenging lifting environments

- Available in M8-M64 and customizable thread options, including extended, shortened, coarse, fine, metric, and UNC threads

- Rated work load limit (WLL) of 0.3-18T

- Safety factor of 4:1, with 100% non-destructive testing

- Each load-bearing component is stamped with a production batch number for traceability

- Forged from high-strength chromium-molybdenum alloy steel, quenched and tempered for enhanced strength and toughness

- Features an epoxy resin electrostatic powder coating for the ring body and Dacromet rust-proof treatment for the bolt

Specifications

(Available in Metric Thread and UNC Thread)

| Item No. | Working Load Limit (t) | M | Dimensions (mm) | Torque (Nm) | Weight (kg) | ||||||||||

| E | A | B | C | D | F | J | H | W | G | S | |||||

| | 0.30 | 8×1.25 | 12 | 36.5 | 25 | 10 | 10.0 | 25 | 41 | 6 | 44 | 25 | 6 | 10-40 | 0.14 |

| | 0.40 | 10×1.5 | 15 | 36.5 | 25 | 10 | 10.0 | 26 | 41 | 6 | 44 | 25 | 6 | 10-40 | 0.15 |

| | 0.75 | 12×1.75 | 18 | 44.5 | 30 | 11 | 11.0 | 33 | 47 | 7 | 52 | 30 | 8 | 15-40 | 0.23 |

| | 1.50 | 16X2.0 | 24 | 50.5 | 35 | 15 | 13.0 | 36 | 58 | 11 | 61 | 35 | 10 | 45-130 | 0.39 |

| | 2.30 | 20×2.5 | 30 | 58.0 | 40 | 17 | 15.0 | 44 | 68 | 14 | 70 | 40 | 12 | 100-170 | 0.65 |

| | 3.20 | 24X3.0 | 36 | 71.0 | 49 | 20 | 17.5 | 53 | 75 | 15 | 84 | 49 | 14 | 190-280 | 1.10 |

| | 4.50 | 30x3.5 | 45 | 88.0 | 61 | 25 | 22.0 | 66 | 95 | 23 | 105 | 60 | 17 | 270-600 | 2.13 |

| | 7.00 | 36×4.0 | 54 | 106.0 | 73 | 30 | 26.5 | 76 | 116 | 31 | 126 | 74 | 22 | 270-600 | 3.70 |

| | 9.00 | 42×4.5 | 63 | 122.0 | 83 | 35 | 32.0 | 89 | 137 | 38 | 147 | 84 | 24 | 350-800 | 5.60 |

| | 12.00 | 48×5.0 | 72 | 141.5 | 95 | 39 | 38.0 | 105 | 151 | 38 | 168 | 98 | 27 | 350-800 | 8.60 |

| | 16.00 | 56×5.5 | 84 | 160.5 | 110 | 49 | 48.0 | 125 | 180 | 49 | 168 | 110 | 27 | 350-801 | 14.50 |

| | 18.00 | 64×6.0 | 96 | 164.0 | 110 | 49 | 48.0 | 125 | 180 | 49 | 168 | 110 | 27 | 350-802 | 15.20 |

* Safety factor of 4:1;

* The length and thread of bolts can be made according to requirements;

Working Load Applications

| Lifting Method | |||||||||||

| Number of Sling Legs | 1 | 2 | 1 | 2 | 2 | 2 | 3-4 | 3-4 | |||

| Lifting Angle | 0° | 0° | 90° | 90° | 0-45° 45-60° | Asymmetry | 0-45° 45-60° | Asymmetry | |||

| Item No. | Thread M | Working Load Limit (t) | |||||||||

| BLT103-M8 | 8×1.25 | 1 | 2 | 0.3 | 0.60 | 0.42 | 0.30 | 0.30 | 0.63 | 0.45 | 0.30 |

| BLT103-M10 | 10×1.5 | 1 | 2 | 0.4 | 0.80 | 0.56 | 0.40 | 0.40 | 0.80 | 0.60 | 0.40 |

| BLT103-M12 | 12×1.75 | 2 | 4 | 0.75 | 1.50 | 1.00 | 0.75 | 0.75 | 1.50 | 1.10 | 0.75 |

| BLT103-M16 | 16×2.0 | 4 | 8 | 1.5 | 3.00 | 2.10 | 1.50 | 1.50 | 3.10 | 2.20 | 1.50 |

| BLT103-M20 | 20×2.5 | 6 | 12 | 2.3 | 4.60 | 3.20 | 2.30 | 2.30 | 4.80 | 3.40 | 2.30 |

| BLT103-M24 | 24×3.0 | 8 | 16 | 3.2 | 6.40 | 4.50 | 3.20 | 3.20 | 6.70 | 4.80 | 3.20 |

| BLT103-M30 | 30×3.5 | 12 | 24 | 4.5 | 9.00 | 6.30 | 4.50 | 4.50 | 9.40 | 6.70 | 4.50 |

| BLT103-M36 | 36×4.0 | 16 | 32 | 7 | 14.00 | 9.80 | 7.00 | 7.00 | 14.70 | 10.50 | 7.00 |

| BLT103-M42 | 42×4.5 | 24 | 48 | 9 | 18.00 | 12.60 | 9.00 | 9.00 | 18.90 | 13.50 | 9.00 |

| BLT103-M48 | 48×5.0 | 32 | 64 | 12 | 24.00 | 16.80 | 12.00 | 12.00 | 25.00 | 18.00 | 12.00 |

| BLT103-M56 | 56×5.5 | 34 | 68 | 16 | 32.00 | 22.40 | 16.00 | 16.00 | 33.60 | 24.00 | 16.00 |

| BLT103-M64 | 64x6.0 | 36 | 72 | 18 | 36.00 | 25.00 | 18.00 | 18.00 | 37.50 | 27.00 | 18.00 |

| Item No. | Working Load Limit (t) | Thread | Dimensions (mm) | Torque (Nm) | Weight (kg) | |||||||||||

| M | TPI | E | A | B | C | D | F | J | H | W | G | S | ||||

| | 0.30 | 5/16 | 18.0 | 12 | 36.5 | 25 | 10 | 10.0 | 25 | 41 | 6 | 44 | 25 | 6 | 10-40 | 0.18 |

| | 0.40 | 3/8 | 16.0 | 15 | 36.5 | 25 | 10 | 10.0 | 26 | 41 | 6 | 44 | 25 | 6 | 10-40 | 0.28 |

| | 0.75 | 7/16 | 14.0 | 18 | 44.5 | 30 | 11 | 11.0 | 33 | 47 | 7 | 52 | 30 | 8 | 15-40 | 0.43 |

| | 0.75 | 1/2 | 13.0 | 18 | 44.5 | 30 | 11 | 11.0 | 33 | 47 | 7 | 52 | 30 | 8 | 15-40 | 0.43 |

| | 1.50 | 5/8 | 11.0 | 24 | 50.5 | 35 | 15 | 13.0 | 36 | 58 | 11 | 61 | 35 | 10 | 45-130 | 0.63 |

| | 2.30 | 3/4 | 10.0 | 30 | 58.0 | 40 | 17 | 15.0 | 44 | 68 | 14 | 70 | 40 | 12 | 45-130 | 0.73 |

| | 2.30 | 7/8 | 9.0 | 33 | 58.0 | 40 | 17 | 15.0 | 44 | 68 | 14 | 70 | 40 | 12 | 100-170 | 0.73 |

| | 3.20 | 1 | 8.0 | 38 | 71.0 | 49 | 20 | 17.5 | 53 | 75 | 15 | 84 | 49 | 14 | 190-280 | 1.13 |

| | 4.50 | 1-1/4 | 7.0 | 48 | 88.0 | 61 | 25 | 22.0 | 66 | 95 | 23 | 105 | 60 | 17 | 270-600 | 2.16 |

| | 7.00 | 1-1/2 | 6.0 | 57 | 106.0 | 73 | 30 | 26.5 | 76 | 116 | 31 | 126 | 74 | 22 | 270-600 | 3.90 |

| | 9.00 | 1-3/4 | 5.0 | 66 | 122.0 | 83 | 35 | 32.0 | 89 | 137 | 38 | 147 | 84 | 24 | 350-800 | 5.60 |

| | 12.00 | 2 | 4.5 | 76 | 141.5 | 95 | 39 | 38.0 | 105 | 151 | 38 | 168 | 98 | 27 | 350-800 | 8.90 |

* Safety factor of 4:1;

* The length and thread of bolts can be made according to requirements;

Working Load Applications

| Lifting Method | |||||||||||

| Number of Sling Legs | 1 | 2 | 1 | 2 | 2 | 2 | 3-4 | 3-4 | |||

| Lifting Angle | 0° | 0° | 90° | 90° | 0-45 | 45-60 | Asymmetry | 0-45° | 45-60° | Asymmetry | |

| Item No. | Thread M | Working Load Limit (t) | |||||||||

| BLT103-5/16 | 5/16 | 1 | 2 | 0.30 | 0.6 | 0.42 | 0.30 | 0.30 | 0.63 | 0.45 | 0.30 |

| BLT103-3/8 | 3/8 | 1 | 2 | 0.40 | 0.8 | 0.56 | 0.40 | 0.40 | 0.80 | 0.60 | 0.40 |

| BLT103-7/16 | 7/16 | 2 | 4 | 0.75 | 1.5 | 1.00 | 0.75 | 0.75 | 1.50 | 1.10 | 0.75 |

| BLT103-1/2 | 1/2 | 2 | 4 | 0.75 | 1.5 | 1.00 | 0.75 | 0.75 | 1.50 | 1.10 | 0.75 |

| BLT103-5/8 | 5/8 | 4 | 8 | 1.50 | 3.0 | 2.10 | 1.50 | 1.50 | 3.10 | 2.20 | 1.50 |

| BLT103-3/4 | 3/4 | 6 | 12 | 2.30 | 4.6 | 3.20 | 2.30 | 2.30 | 4.80 | 3.40 | 2.30 |

| BLT103-7/8 | 7/8 | 6 | 12 | 2.30 | 4.6 | 3.20 | 2.30 | 2.30 | 4.80 | 3.40 | 2.30 |

| BLT103-1 | 1 | 8 | 16 | 3.20 | 6.4 | 4.50 | 3.20 | 3.20 | 6.70 | 4.80 | 3.20 |

| BLT103-1-1/4 | 1-1/4 | 12 | 24 | 4.50 | 9.0 | 6.30 | 4.50 | 4.50 | 9.40 | 6.70 | 4.50 |

| BLT103-1-1/2 | 1-1/2 | 16 | 32 | 7.00 | 14.0 | 9.80 | 7.00 | 7.00 | 14.70 | 10.50 | 7.00 |

| BLT103-1-3/4 | 1-3/4 | 24 | 48 | 9.00 | 18.0 | 12.60 | 9.00 | 9.00 | 18.90 | 13.50 | 9.00 |

| BLT103-2 | 2 | 32 | 64 | 12.00 | 24.0 | 16.80 | 12.00 | 12.00 | 25.00 | 18.00 | 12.00 |

Related products

Send Message

Other Products

Most Recent

More

Other Products

Videos