Hydraulic Motor

Built for reliability in the toughest conditions, our hydraulic piston motors combine high-quality materials with advanced manufacturing techniques to deliver stable performance. Designed specifically for high-speed, high-pressure applications, these motors provide efficient power output and long-lasting durability, making them an ideal choice for construction machinery, agricultural equipment, mining, and more.

Our dedicated R&D team has enhanced these motors with innovative materials and leading-edge technology to maximize operational efficiency and extend service life. Whether you’re working in construction, mining, or on an offshore platform, our new piston motors offer the high-pressure, high-power output your equipment demands.

We know that every project is unique, which is why we emphasize customization. From design to production, we work with you to create a hydraulic motor that meets your exact specifications and application needs.

Where Our Closed-Circuit Hydraulic Piston Motors Excel

Perfect for hydrostatic drive systems, our closed-circuit hydraulic piston motors offer flexible control, easy installation, strong overload protection, and high integration. Common applications include:

- Agricultural Machinery: Rice, wheat, corn, and soybean harvesters, high-clearance sprayers, sugarcane harvesters, self-propelled mowers, and forage harvesters.

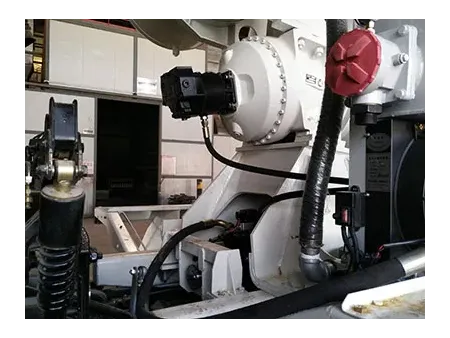

- Construction Equipment: Hydraulic drive systems for vibratory rollers, asphalt pavers, concrete mixers, and concrete pump trucks.

- Heavy-Duty Transport: Hydrostatic-driven forklifts, tire and track cranes, large transport vehicles, and self-propelled flatbed carriers.

- Loaders and Dozers: Hydrostatic wheel and track loaders, skid steers, track dozers, and mining scrapers.

- Specialized Vehicles: Hydrostatic aircraft tow vehicles, de-icers, and snowplows.

- Oil & Gas and Snow Applications: Exploration vehicles, controlled seismic source carriers, submersible transporters, tracked snow vehicles, and snow groomers.

- Self-propelled sprayer

- Concrete mixer drum

A hydraulic motor converts fluid pressure into rotational motion. Pressurized fluid from a hydraulic pump moves the motor’s gears, pistons, or vanes, turning the motor's output shaft.

The three main types of hydraulic motors are gear motors, piston motors, and vane motors.

In a piston hydraulic motor, pistons are connected to a shaft via connecting rods. When fluid enters the motor, the pistons move up and down in the cylinder, causing the shaft to rotate. Piston motors are commonly used in construction equipment because they generate high torque.

There are two common types of piston hydraulic motors: axial piston motors and radial piston motors.

An axial piston motor is one of the most commonly used types of hydraulic motors. It works by using a series of pistons in a cylinder block to create linear motion, making it ideal for hydraulic systems that require high torque, such as construction equipment.

Hydraulic motors are among the most versatile and widely used motors in the world. They’re suitable for applications ranging from small household devices to large industrial machinery. The main benefits of using hydraulic motors include:

- Higher operational efficiency.

- Greater power density during operation.

- A wide range of operating speeds, making them compatible with various hydraulic equipment.

- Durability and ease of maintenance.