Pure Nickel

Request a Quote

Commercially pure nickel

Pure Nickel Wire

Your Trusted Source for Pure Nickel Manufacturing

Pure nickel are primarily composed of nickel (Ni) with small amounts of elements like copper, iron, cobalt, or chromium to enhance specific properties. These alloys are known for their excellent electrical conductivity, corrosion resistance, high-temperature mechanical strength, and find their main application in electronics, chemical processing, aerospace, and battery sectors.

Available grades: N4, N6, Ni200, Ni201

- Wire

- Wire Diameter: 0.02mm-10mm

- Straight Wire: Length: 500mm-2000mm

- Surface Condition: Bright annealed, semi-hard, hard

- Tolerance: ±0.005mm-±0.05mm (depending on wire diameter)

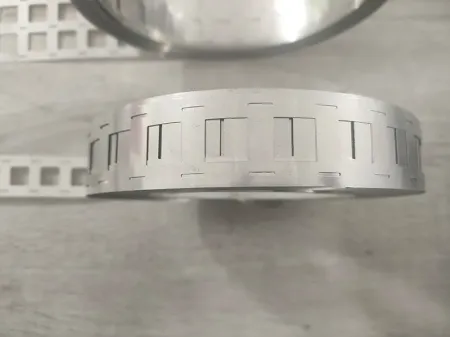

- Strip

- Thickness: 0.01mm-3mm

- Width: 5mm-455mm

- Strip Roll: 100m-1000m/roll (depending on thickness and width)

- Hardness Condition: Soft, 1/2H, 1/4H, hard

- Thickness Tolerance: ±0.005mm-±0.02mm

- Width Tolerance: ±0.1mm-±0.5mm

- Rod

- Diameter: 1mm-200mm

- Length: 100mm-3000mm, or customizable

- Tube

- Outer Diameter: 6mm-300mm

- Wall Thickness: 0.5mm-20mm

- Length: 100mm-6000mm, or customizable

Standard Compliant

Our production adheres to JIS G4313 standards, ensuring compliance with international quality benchmarks.

Equivalent overseas standards are listed for reference.

- ISO 6207

- ASTM B162

- GB/T 2072

Chemical Composition

| Grade | Nickel (Ni) Cobalt (Co) | Copper (Cu) | Silicon (Si) | Manganese (Mn) | Carbon (C) | Magnesium (Mg) | Sulfur (S) | Phosphorus (P) | Iron (Fe) |

| 99.9% | ≤0.015 | ≤0.03 | ≤0.002 | ≤0.01 | ≤0.01 | ≤0.001 | ≤0.001 | ≤0.04 | |

| 99.6% | 0.1 | 0.1 | 0.05 | 0.1 | 0.1 | 0.005 | 0.002 | 0.1 |

Physical & Mechanical Properties

| Grades | N4/Ni201 | N6/Ni200 |

| Density | 8.9g/cm³ | 8.9g/cm³ |

| Melting Point | 1455°C | 1445-1470℃ |

| Coefficient of Thermal Expansion | 13.0µm/m·°C | 13.3×10⁻⁶/℃ |

| Thermal Conductivity | 10.1W/m·K | 90.7 W/m·K |

| Electrical Resistivity | 0.103×10⁻⁶Ω·/m (at 20℃) | |

| Electrical Conductivity | 14.6% IACS | |

| Tensile Strength | ≥450MPa | ≥450 MPa |

| Yield Strength | ≥200MPa | ≥150 MPa |

| Elongation at Break | ≥40% | ≥40% |

| Hardness | ≤150 |

Features

- Excellent electrical conductivity makes it ideal for use in electronic and electrical components

- Superior corrosion resistance performance in reducing environments, except in strong alkaline conditions

- Easily processed into complex shapes under hot or cold conditions with good weldability and formability

- Stable coefficient of thermal expansion for applications requiring temperature stability

- High-temperature strength & ductility maintains mechanical integrity even at elevated temperatures

- Some variants are shape memory alloys, allowing them to return to their original shape under specific temperature conditions

Applications

- Chemical & electroplating industry: Used in reactor vessels, pipelines, and corrosion-resistant equipment

- Electronics & battery industry: Found in lithium battery connectors, sputtering targets, and electrical contacts

- Aerospace: Applied in aircraft engine components and spacecraft parts

- Automotive manufacturing: Used in battery system components for electric vehicles

- Metal stamping & hardware: Ideal for high-strength and corrosion-resistant small components

- Telecommunications & vacuum electronics: Used in specialty bulbs, radio components, and vacuum devices

- Medical equipment: Selected for non-magnetic implants and surgical devices

- Diamond tools: Acts as a metallic binder to enhance durability and cutting efficiency

Packaging