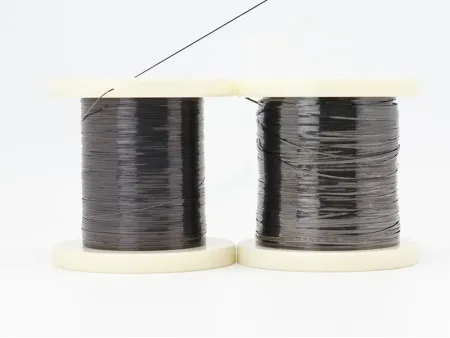

Nickel Titanium Alloy (Nitinol)

Nickel Titanium (also known as Nitinol or NiTi) is in the unique class of shape memory alloys. A thermoelastic martensitic phase transformation in the material is responsible for its extraordinary properties. Nitinol alloys are typically made of 55%-56% Nickel and 44%-45% Titanium. Small changes in composition can significantly impact the properties of the material. There are two primary categories of Nitinol.

Nickel-Titanium alloy, commonly known as Nitinol, is a high-performance material characterized by its unique thermoelastic martensitic phase transformation. This property enables both a shape-memory effect and superelasticity, allowing the alloy to return to a preset shape when heated or recover its original form after considerable deformation. These adaptive mechanical behaviors make Nitinol ideal for precision applications. The alloy typically consists of 55-56% nickel and 44-45% titanium, and even minor compositional adjustments can significantly impact its performance.

| Diameter | ⌀0.08 mm - ⌀10.0 mm |

| Length | Customizable |

| Surface Finish | Bright finish, matte finish (sandblasted), or oxidized finish |

| Outer Diameter | ⌀0.8 mm - ⌀114 mm |

| Wall Thickness | 0.08 mm - 8 mm, or customizable |

| Length | ≤ 18000 mm, or customizable |

| Surface Finish | Pickled, bright finish, polished |

- Shape memory activation with >98% recovery in single-cycle tests

- Superelastic recovery with tensile strength ≥850 MPa (in superelastic state)

- Biocompatible titanium oxide surface compliant with ASTM F2063

- Medical: Used in self-expanding stents for minimally invasive vascular surgeries and orthodontic archwires providing gentle, continuous force

- Aerospace Deployed in thermally activated satellite antenna components using solar energy

- Consumer products: Integrated into highly resilient and durable eyeglass frames that are resistant to deformation, and provides a comfortable fit

- Industrial safety: Applied in temperature-sensitive fire damper springs in HVAC systems