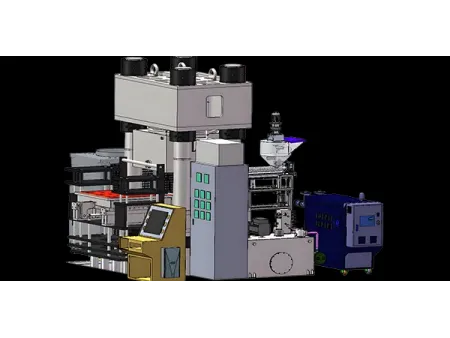

SMC Injection Compression Molding Press

Engineered for high-efficiency compression molding, this molding press is ideal for forming a wide range of materials including thermoset plastics, rubber, metals, resins, ceramics, and composites.

Widely applied in industries such as automotive, electrical, and construction, the sheet molding compound (SMC) injection compression molding process is particularly suited for producing phenolic plastics, urea-formaldehyde plastics, and other heat-cured resin-based components. Our press delivers consistent pressure and thermal control, making it suitable for both structural and aesthetic applications that require dimensional stability and surface precision.

| Model | Unit | |||||

| Clamping force | kN | 1000 | 2000 | 3000 | 5000 | |

| Injection pressure | kN | 100 | 150 | 200 | 200 | |

| Max. stroke of lower heating platen | mm | 400 | 400 | 400 | 400 | |

| Max. open daylight | mm | 250- 400 | 250- 400 | 250- 600 | 250- 600 | |

| Max. stroke of moving table | mm | 800 | 1000 | 1000 | 1100 | |

| Effective area of heating platen | F-B | mm | 650 | 500 | 1000 | 650 |

| L-R | mm | 650 | 500 | 1000 | 650 | |

| Max. temperature | ℃ | 100-400 | 100-400 | 100-400 | 100-400 | |

| Number of temperature controlled heating zones | Zones | 3 | 3 | 3 | 3 | |

The injection compression molding process involves injecting liquid or semi-solid materials into a mold cavity, then applying pressure to ensure the material fills the mold completely before being cooled and demolded.

This method combines the benefits of injection and compression molding, offering precise control over temperature, pressure, and material flow. Our molding press system features an advanced temperature and pressure regulation system, allowing for highly consistent processing conditions. This results in excellent dimensional accuracy, surface quality, and material integrity, particularly important for thermoset plastic products and high-performance composite parts.