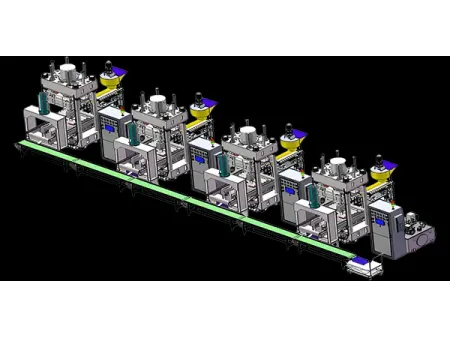

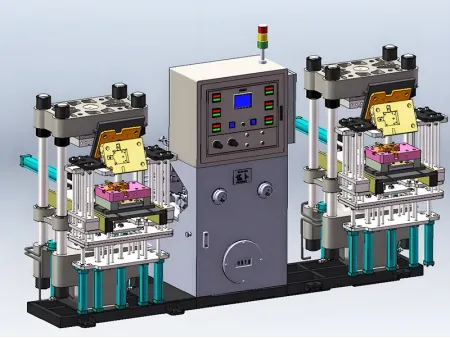

Rubber Vulcanizing Press

The rubber vulcanizing press is designed for the molding and vulcanizing of rubber and composite materials, using a high-temperature, high-pressure process to cure raw rubber into durable, elastic components. Widely used in the production of tires, rubber hoses, sheets, and high-performance polyimide composite parts, this press ensures consistent elasticity, wear resistance, and shape retention across various molded rubber products.

| Capacity | 10T-1500T (or customizable) |

| Heating method | Electric heating/oil heating |

| Temperature range | Room temperature to 300℃ |

| Temperature accuracy | ±1.0℃ |

| Heating platen size | Customizable |

| Cooling platen size | Customizable |

| Working layers | Customizable |

| Total power | Customizable |

| Operation mode | Automatic/manual operation |

The press applies high temperature and hydraulic pressure to initiate chemical cross-linking in rubber compounds, transforming them into finished products with specific mechanical and thermal properties. Heat is supplied via steam, thermal oil, or hot water, while pressure is generated through a hydraulic cylinder system.

The vulcanizing press consists of key components such as the frame, hydraulic cylinder, heating plates, and molds. It is available in various configurations to suit specific production needs: