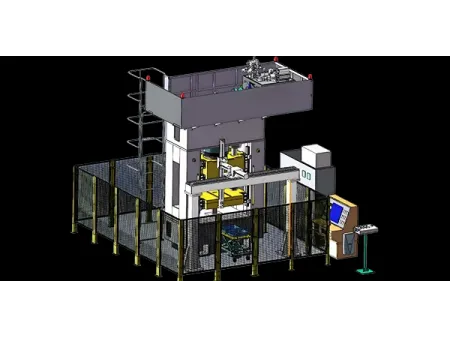

Heated Platen Press (Vacuum Hot Press)

Designed for precision thermoforming under vacuum, the heated platen press is ideal for shaping advanced materials such as carbon fiber, fiberglass, graphite, and various high-performance alloys and polymers that are not able to be produced using melting techniques.

Commonly used for manufacturing carbon fiber phone casings, fiberglass panels, and graphite components, the vacuum hot press also supports the hot forming of titanium and aluminum alloys, SMC materials, engineering plastics, and high-precision rubber parts. The vacuum hot press offers several benefits over traditional sintering or hot-pressing methods conducted in normal atmospheres, by ensuring minimal oxidation, minimized contamination, and improved surface quality.

| Model | Unit | ||||||||

| Nominal force | kN | 500 | 1000 | 1500 | 2000 | 2500 | 3000 | 5000 | |

| Max. stroke of upper heating platen | mm | 400 | 400 | 400 | 400 | 400 | 400 | 400 | |

| Max. open daylight | mm | 500 | 500 | 500 | 550 | 550 | 650 | 650 | |

| Max. stroke of moving table | mm | 600 | 800 | 1000 | 1000 | 1000 | 1000 | 1000 | |

| Effective area of heating platen | F-B | mm | 400 | 500 | 600 | 650 | 650 | 720 | 1000 |

| L-R | mm | 400 | 500 | 600 | 650 | 650 | 720 | 1000 | |

| Max. temperature | ℃ | 950 | 950 | 950 | 950 | 950 | 950 | 950 | |

| Number of temperature controlled heating zones | Zones | 9 | 9 | 9 | 9 | 9 | 9 | 9 | |

| Max stroke of vacuum cover | mm | 300 | 300 | 300 | 300 | 300 | 350 | 400 | |

| Ultimate vacuum | Pa | 0.49 | 0.49 | 0.49 | 0.49 | 0.49 | 0.49 | 0.49 | |

The heated platen press integrates heating, pressure holding, pressure compensation, and vacuum extraction into a single system. In a vacuum environment, the material is heated to the required temperature, then compressed by the upper and lower platens to achieve material densification, impurity removal, and improved part uniformity.

The hot press system is equipped with a servo closed-loop control system, providing energy efficiency, low noise, and precise pressure regulation. Its PLC-based programmable control allows for multi-stage pressure and multi-segment stroke settings, making it ideal for applications that require frequent adjustments to forming parameters or variable processing conditions.

- 10T Heated Platen Press

- 150T Heated Platen Press

- Hot Cold Presses